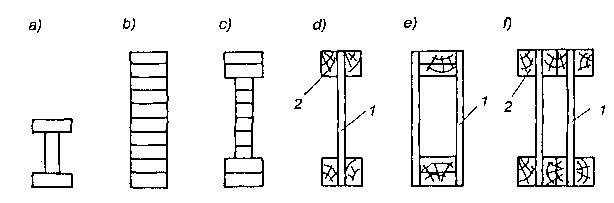

Na rysunku przedstawiono przekroje najczęściej wykonywanych belek i dźwigarów gwoździowanych i klejonych. Prostokątne i dwuteowe przekroje warstwowe (rys. b, c) stosuje się w belkach, łukach lub ramach. Przekroje dwuteowe i skrzynkowe (rys. d, e, f) stosowane są również w dźwigarach oraz ramach.

Przekroje belek i dźwigarów gwoździowych lub klejonych z desek: a), b), c) warstwowe dwuteowe i prostokątne, d) dźwigar dwuteowy, e), f) skrzynkowe; 1 — środnik z desek lub sklejki drewnianej, 2 — półki z desek lub bali.

Przekroje belek i dźwigarów gwoździowych lub klejonych z desek: a), b), c) warstwowe dwuteowe i prostokątne, d) dźwigar dwuteowy, e), f) skrzynkowe; 1 — środnik z desek lub sklejki drewnianej, 2 — półki z desek lub bali.

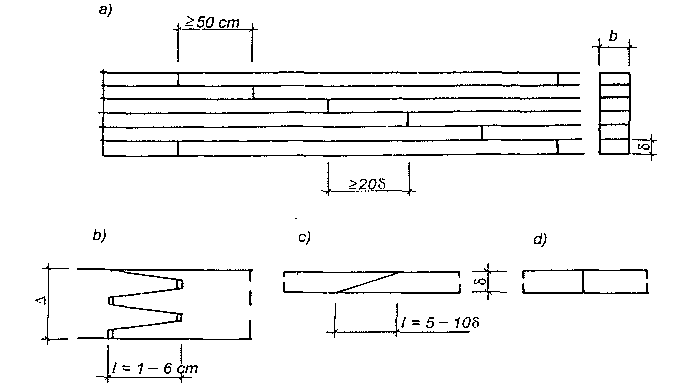

W belkach lub dźwigarach o większej długości od handlowej długości tarcicy — deski, bale i krawędziaki łączone są na długości. W przypadku elementów gwoździowanych o przekroju warstwowym deski łączy się na styk czołowy, w innych elementach na styk czołowy z nakładką, natomiast w elementach klejonych łączy się na styk czołowy lub ukośny.

Belka warstwowa: a) rozmieszczenie styków desek, b), c) złącza klejone klinowe, ukośne, d) styk czołowy.

Belka warstwowa: a) rozmieszczenie styków desek, b), c) złącza klejone klinowe, ukośne, d) styk czołowy.

Styk czołowy przyjmuje się w tych elementach klejonych, które pracują na ściskanie lub są umieszczone w tej strefie belki, w której występują naprężenia ściskające.

Złącza desek (styki) rozmieszcza się mijankowo na długości elementu. W jednym przekroju elementu warstwowego nie powinno być więcej styków niż 25% wszystkich desek. Odległość styków w sąsiednich warstwach (zakład) – wynikająca z możliwości włączenia do współpracy deski sąsiedniej — nie powinna wynosić mniej niż 20 δ lub 50 cm (δ — grubość deski).

Do wykonania konstrukcji gwoździowanych używa się desek, bali, łat i krawędziaków, sklejki drewnianej i materiałów drewnopochodnych oraz gwoździ. Sklejka i materiały drewnopochodne stosowane są na środniki belek i dźwigarów dwuteowych oraz skrzynkowych.

Jako łączniki stosuje się gwoździe okrągłe i kwadratowe. Średnica gwoździ w złączach elementów drewnianych powinna wynosić od 1/6 do 1/11 grubości łączonych elementów, natomiast w złączach z twardych płyt i ze sklejki o grubości do 8 mm, średnicę gwoździ przyjmuje się w granicach 2,0-4,0 mm. Długość gwoździa nie powinna być mniejsza od 1 = δ+ 12 (δ— grubość łączonego elementu, d — Średnica gwoździa).

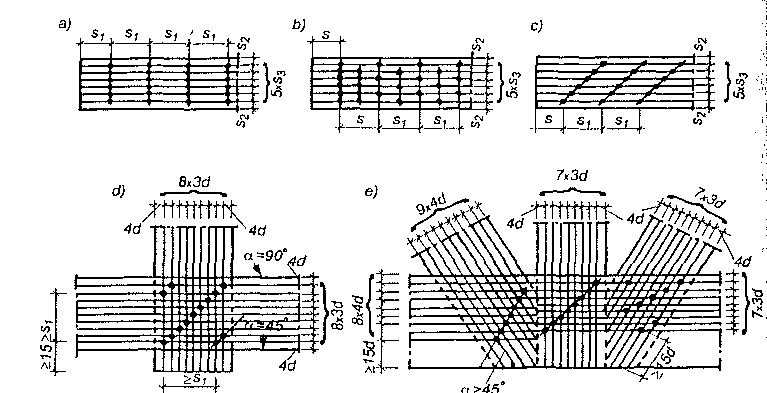

Sposoby rozmieszczenia gwoździ w elementach łączonych równolegle i pod kątem przedstawiono na rysunku.

Rozmieszczenie gwoździ w elementach łączonych: a), b), c) równolegle, d), e) pod kątem.

Rozmieszczenie gwoździ w elementach łączonych: a), b), c) równolegle, d), e) pod kątem.

Do wykonania konstrukcji klejonych używa się tarcicy o grubości do 5,0 cm. Z cieńszej tarcicy uzyskuje się elementy o większej wytrzymałości, odporniejsze na rozwarstwienie i działanie czynników atmosferycznych. Związane jest to jednak z zużyciem większej ilości klejów i większymi stratami drewna spowodowanymi struganiem. Cieńszą tarcicę stosuje się do elementów zakrzywionych, np. węzłów ram. Jeśli promień krzywizny wynosi R = 300δ, przyjmuje się deski o grubości δ = 4,0 cm, natomiast dla R = 200δ przyjmuje się δ = 3,0 cm.

Do klejenia drewna stosowane są kleje: kazeinowe, mocznikowe i rezorcynowe. Klej kazeinowy jest stopniowo wypierany przez inne kleje, dostarczane przez przemysł.