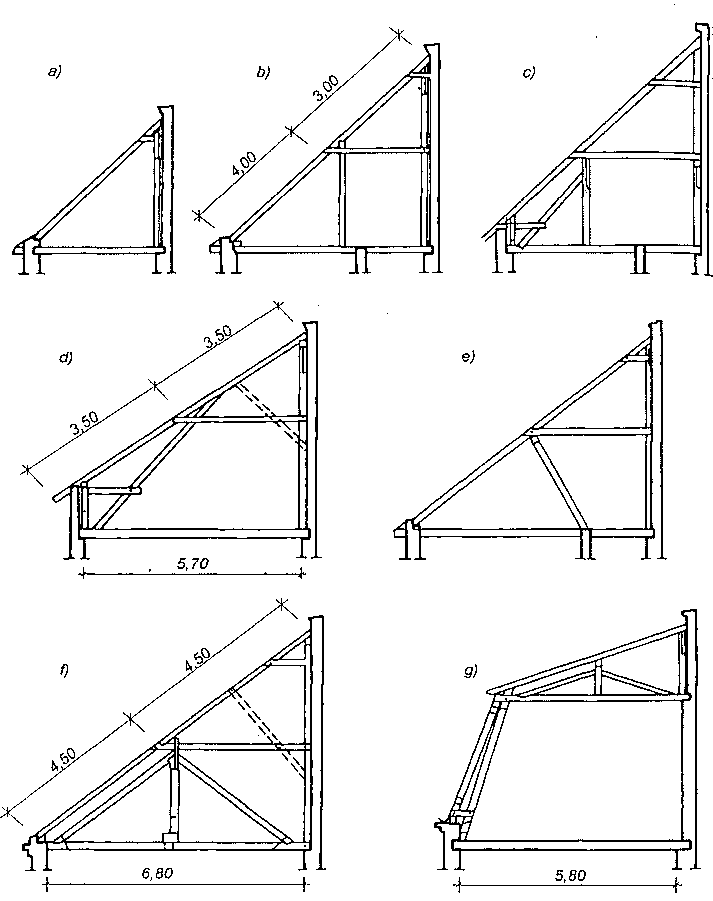

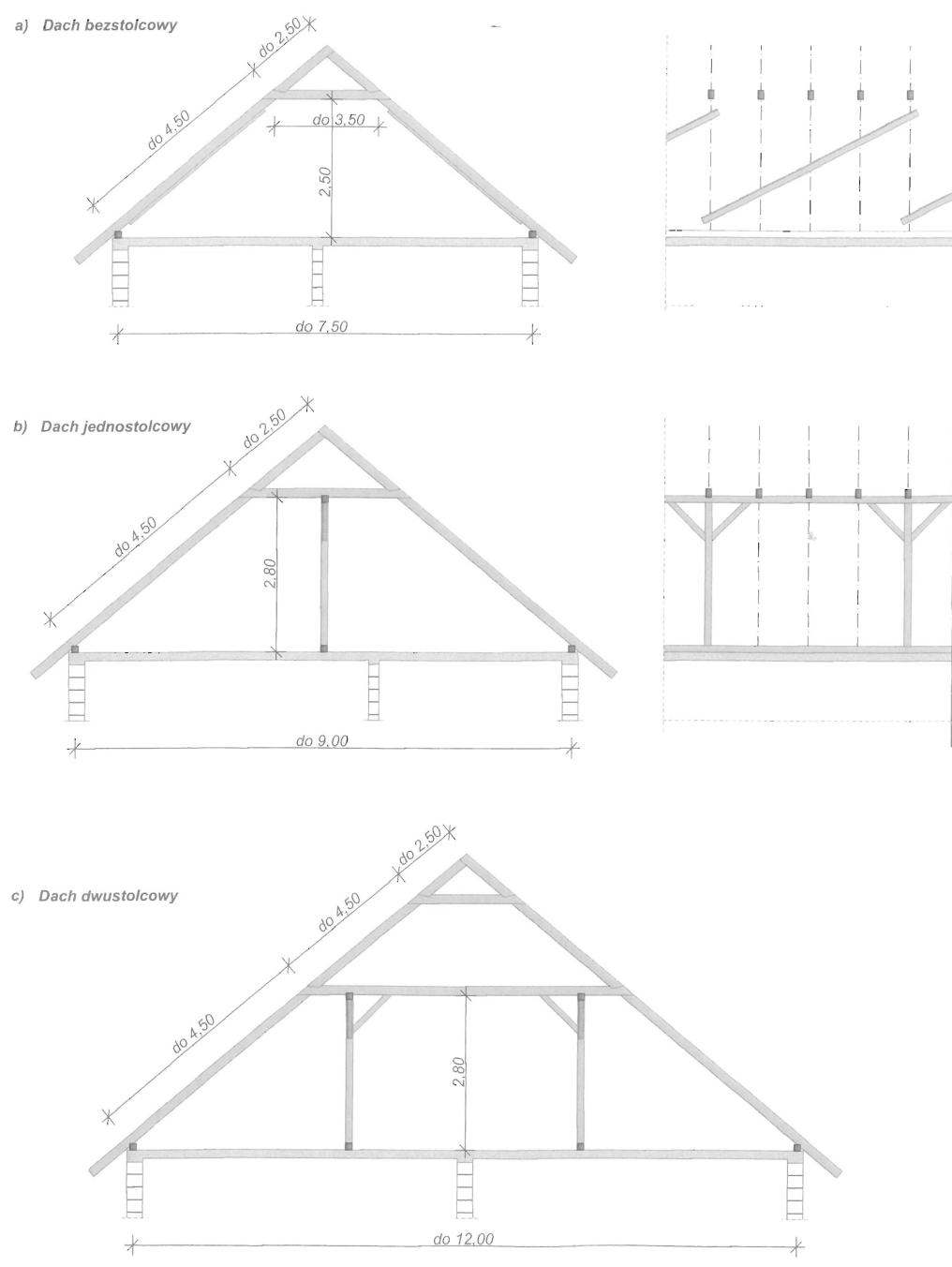

Dachy o konstrukcji jętkowej, o różnych rozpiętościach pomiędzy ścianami zewnętrznymi budynku.

Dachy o konstrukcji jętkowej, o różnych rozpiętościach pomiędzy ścianami zewnętrznymi budynku.

Konstrukcje dachowe:

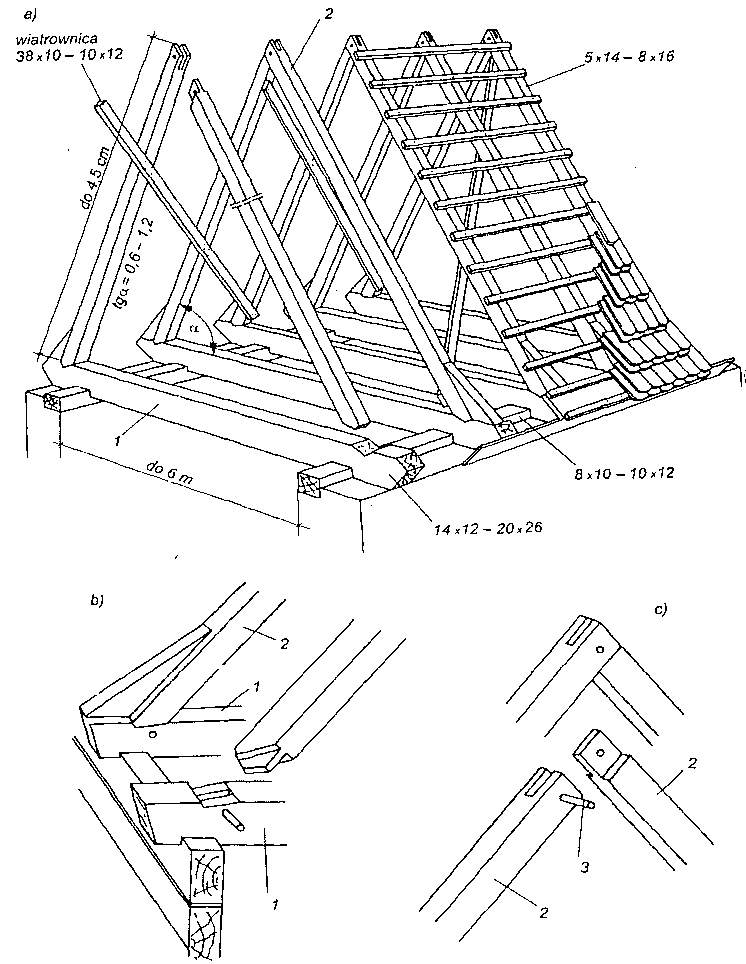

• Więźba krokwiowa (bezsłupowa) – Najprostsza konstrukcja dachowa stosowana, gdy rozpiętość między zewnętrznymi ścianami nośnymi nie przekracza 7,0 m. W więźbie krokwiowej każda z dwóch krokwi tworzących wiązar oparta jest tylko w dwóch miejscach – w kalenicy i na murłacie nad ścianą zewnętrzną. Przed działaniem wiatru więźba krokwiowa zabezpieczana jest przez usztywnienie tzw. wiatrownicami, czyli ukośnie przybitymi deskami. Podstawowym elementem nośnym jest para krokwi połączonych ze sobą w kalenicy o długości 4,5 – 6,0 m, rozstawionych w odstępach od 80 do 120 cm Krokwie łączone są ze sobą w kalenicy na tzw. zwidłowanie lub nakładkę z kołkowaniem. Przekroje krokwi wynoszą od 5 x 14 cm do 5 x 16 cm, w zależności od ich rozstawu i obciążeń. Wymiary murłaty wynoszą najczęściej 10×10 cm. Murłaty przymocowuje się do muru lub wieńca żelbetowego za pomocą kotew stalowych z nakrętką, rozmieszczonych co 2,5 -4,0 m,

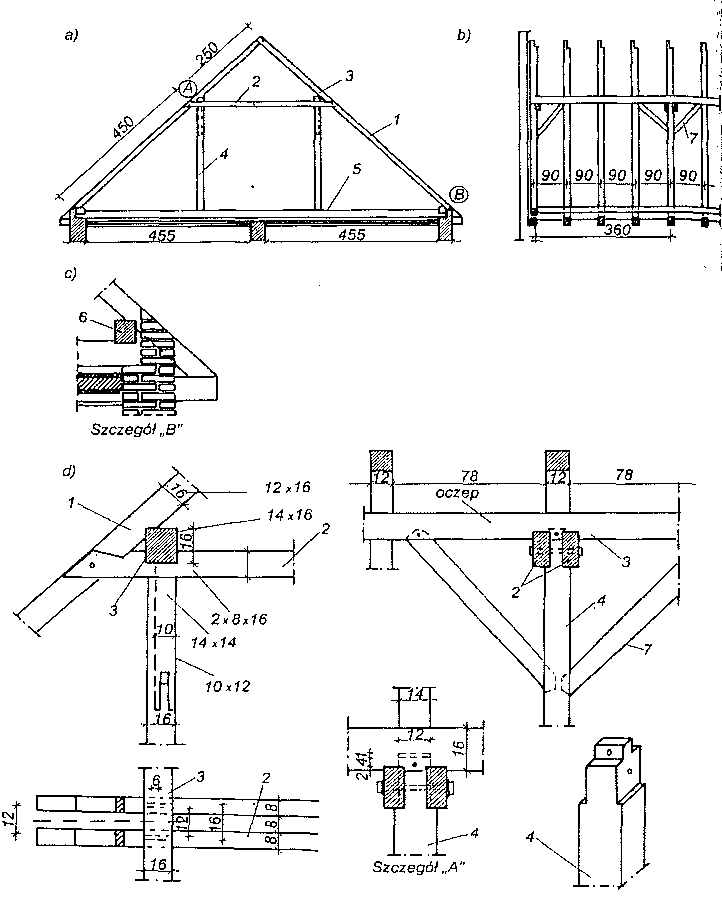

• Więźba jętkowa – Stosowana jest wtedy, gdy rozpiętość między ścianami zewnętrznymi jest większa niż 7,0 m i stosowanie więźby krokwiowej przestaje być ekonomiczne. W więźbie o konstrukcji jętkowej każda para krokwi połączona jest jętką, czyli belką stężającą dwie krokwie. Jętka przenosi siły poziome z jednej krokwi na drugą i w ten sposób krokiew po stronie przeciwnej do kierunku wiatru współpracuje przy przenoszeniu parcia wiatru. Jednocześnie jętka pozwala na zwiększenie rozpiętości krokwi przy działaniu sił pionowych.

Największa rozpiętość dachów jętkowych wynosi 12 m – minimalny zalecany kąt nachylenia krokwi wynosi 35° a maksymalna ich długość

4,5 + 2,7 = 7,2 m. Daje to graniczną rozpiętość wiązara 11,8 m.

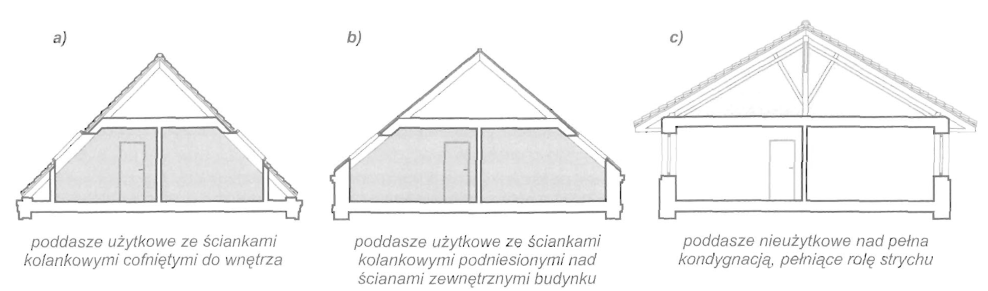

Jętki pełnią funkcję rozpór i dlatego całe obciążenie dachu przenoszone jest na ściany zewnętrzne. Wymaga to zakotwienia murłat i zabezpieczenia ścian kolankowych przed rozsunięciem, poprzez wykonanie dodatkowego wieńca żelbetowego pod murłatą i ewentualnie stężenie go słupkami żelbetowymi z wieńcem stropu nad ostatnią kondygnacją.

W celu większego usztywnienia wiązarów zastosować można dodatkowe płatwie umieszczone nad jętkami (na styku z krokwiami).

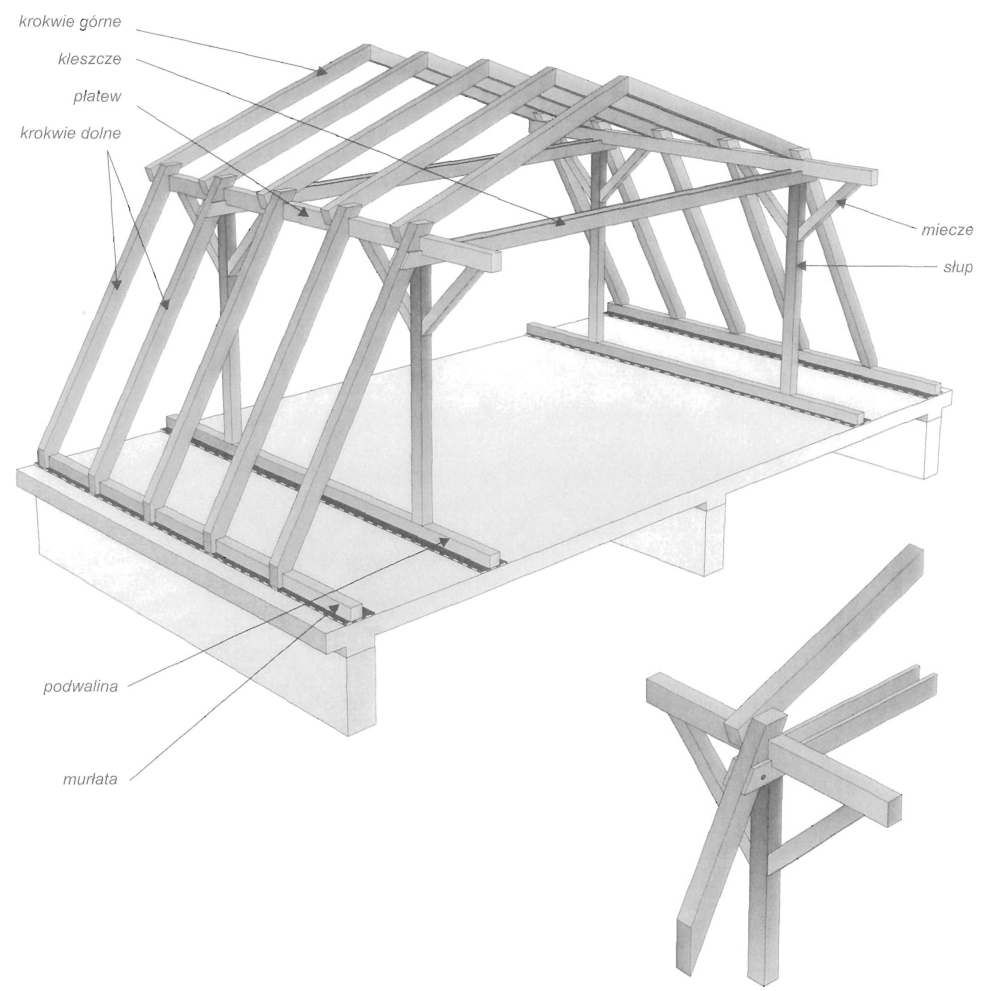

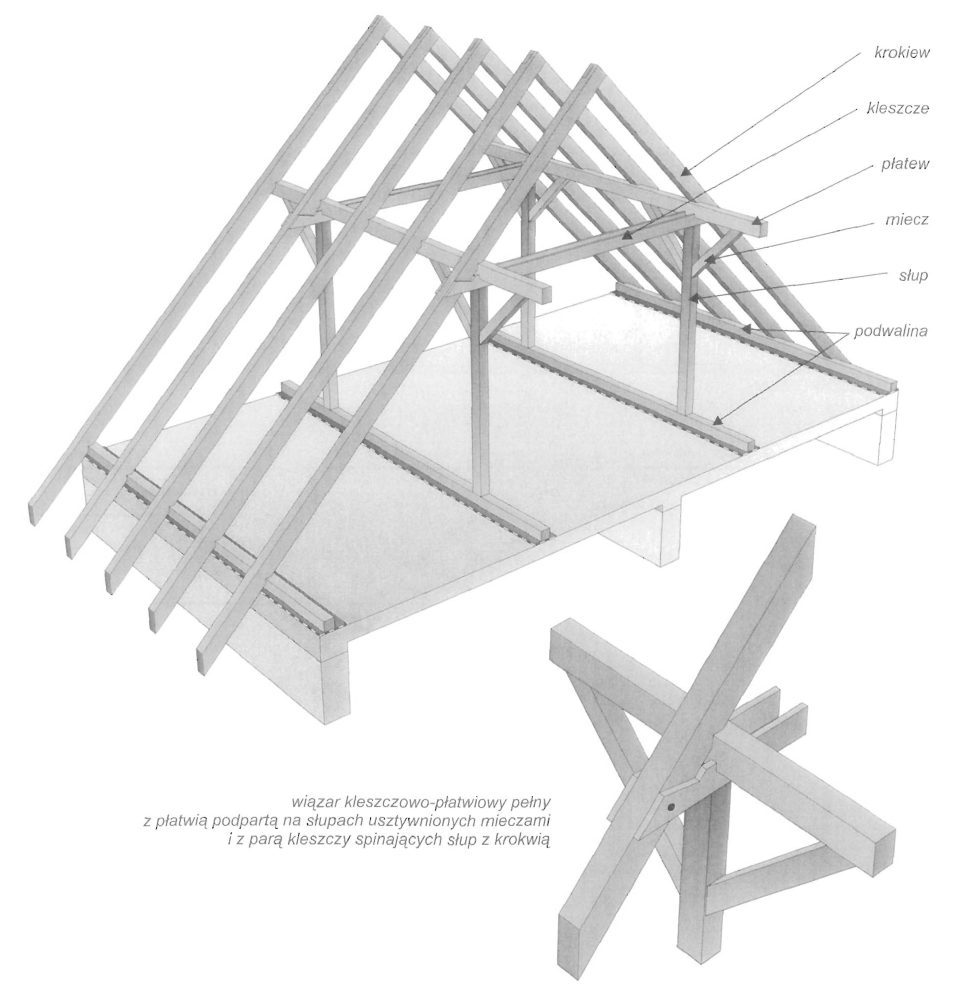

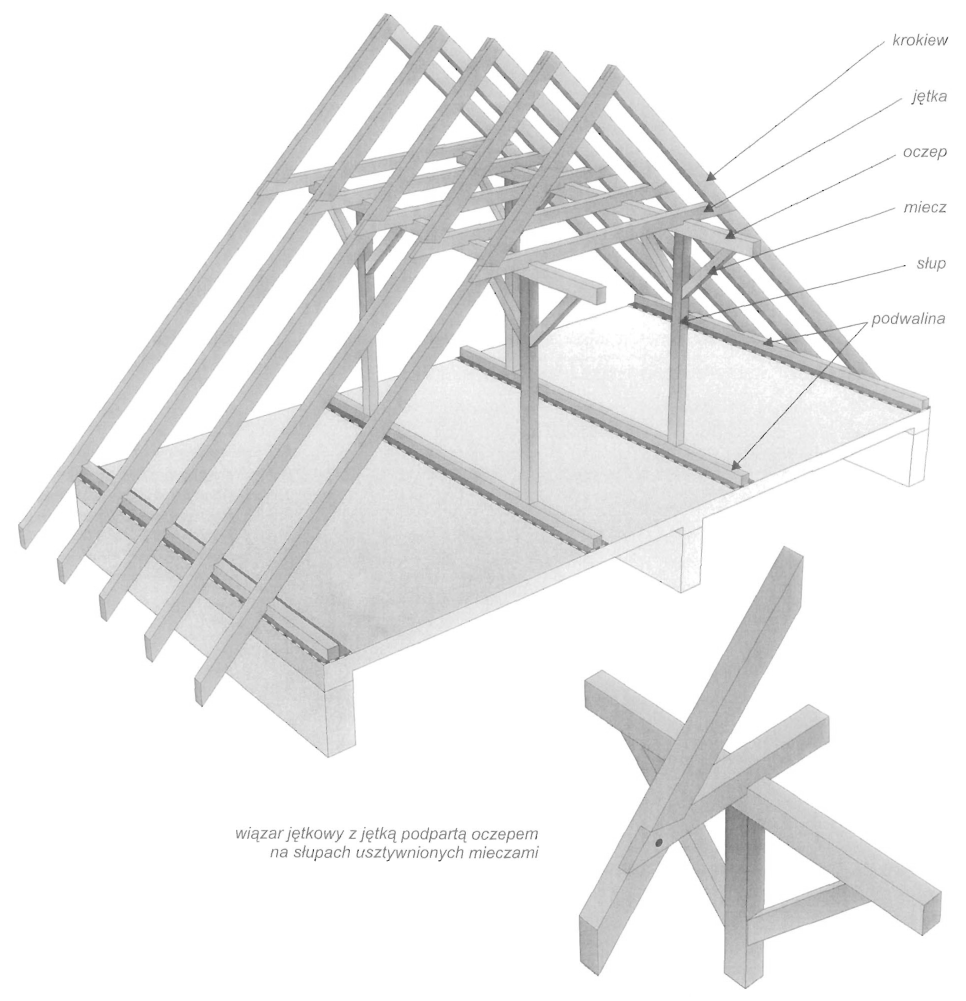

• Więźba płatwiowo-kleszczowa – Stosowana jest zarówno w wypadku stromych jak i łagodnych pochyleń połaci dachowych. Więźba taka polega na oparciu wszystkich krokwi na płatwiach – poziomych belkach podpartych słupami i stężonych z nimi za pomocą mieczy (belek pod kątem 45°, o długości około 1 m). Kleszcze obejmują z obu stron każdą krokiew i słup.

Więźba kleszczowo-płatwiowa jest rozwiązaniem ekonomicznym pod względem ilości użytego drewna, minusem jest brak konstrukcji pozwalającej wykonać strop nad poddaszem.

Podczas gdy w dachu o konstrukcji jętkowej wszystkie obciążenia są przekazywane przez murłaty na ściany zewnętrzne budynku, w dachu kleszczowo-płatwiowym większość obciążeń jest przekazywana przez słupy podpierające płatwie na konstrukcję stropu poddasza, a tylko część obciążeń przejmują ściany zewnętrzne.

Dla różnych typów konstrukcji jest wiele elementów projektu, które rozwiązuje się podobnie:

• Dachy jednospadowe (pulpitowe) – W żadnym wypadku ściana pulpitowa nie może przejmować jakichkolwiek obciążeń poziomych od więźby dachowej, lecz musi być przez więźbę usztywniona i utrzymywana ze względu na ssanie lub parcie wiatru.

• Otwory dachowe – Wykonuje się w celu wentylacji lub oświetlenia poddasza, albo jako włazy dachowe. Najczęściej otwór umieszcza się pomiędzy krokwiami i wtedy jego szerokość jest równa rozstawowi krokwi. Gdy otwór jest większy od rozstawu krokwi, wówczas środkową krokiew opiera się na wymianie.

• Oparcie więźby dachowej na ścianach – W miejscach zetknięcia się z murem, betonem itp. elementy więźby powinny być odizolowane dwiema warstwami papy.