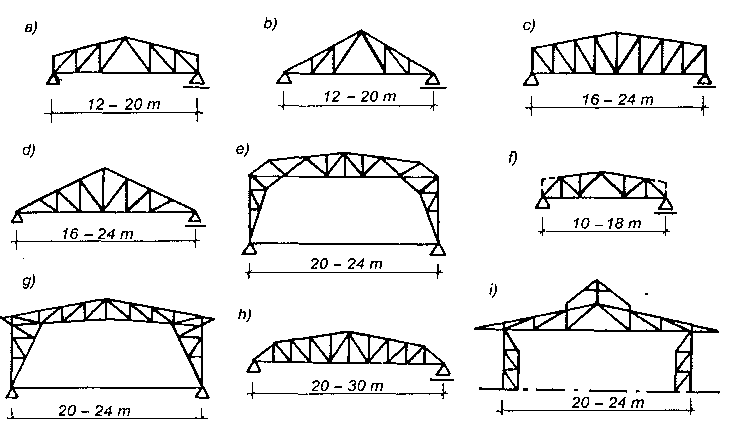

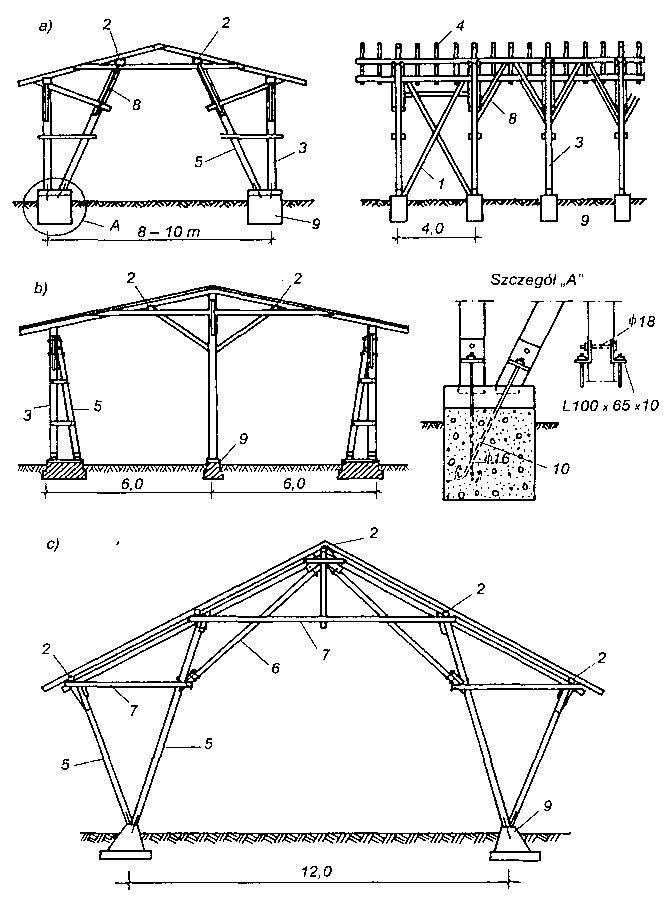

Rozpiętość przekryć w inżynierskich konstrukcjach drewnianych sięga kilkudziesięciu metrów. Cechuje je lekkość, oszczędność w zużyciu drewna i różnorodność rozwiązań konstrukcyjnych.

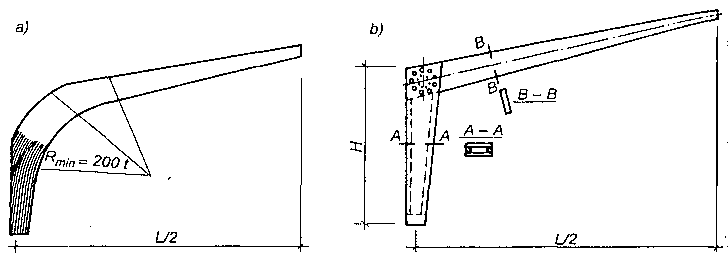

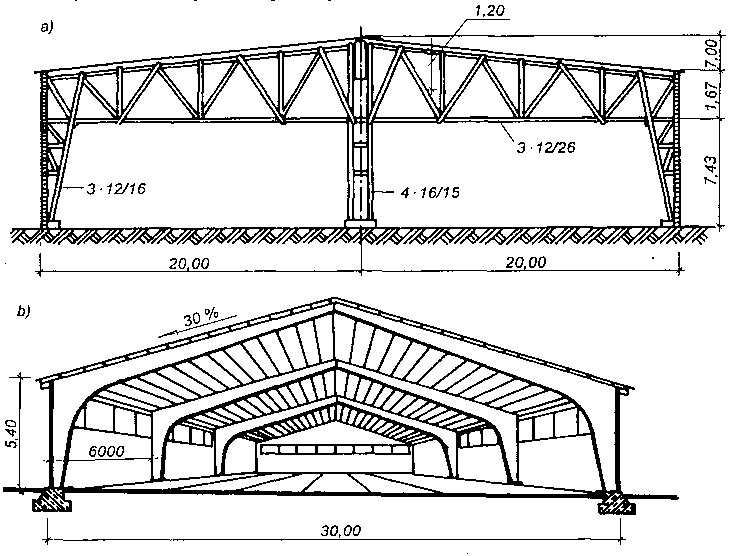

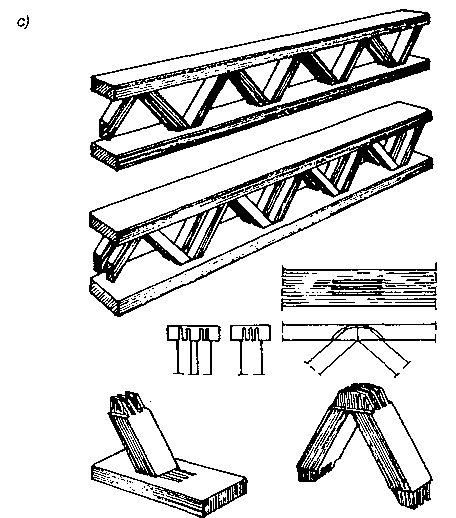

Konstrukcje inżynierskie: a) rama kratowa dwuprzęsłowa, b) ramy trójprzegubowe z drewna klejonego, c) dźwigary kratowe z drewna klejonego.

Konstrukcje inżynierskie: a) rama kratowa dwuprzęsłowa, b) ramy trójprzegubowe z drewna klejonego, c) dźwigary kratowe z drewna klejonego.

W konstrukcji ciesielskiej wykonywano przeważnie budynki jedno- lub dwukondygnacyjne (budynki nie przeznaczone na mieszkanie mogą mieć inne wysokości).

Przez długi okres ściany budynków drewnianych wykonywano jako ściany wieńcowe lub słupowo-ryglowe (szkieletowe). Od kilkudziesięciu już lat wykonuje się ściany z elementów prefabrykowanych wytwarzanych z drewna i materiałów drewnopochodnych. Takie elementy składowe budynku, jak ściany, stropy i dach wykonywane są w zakładach poza placem budowy.

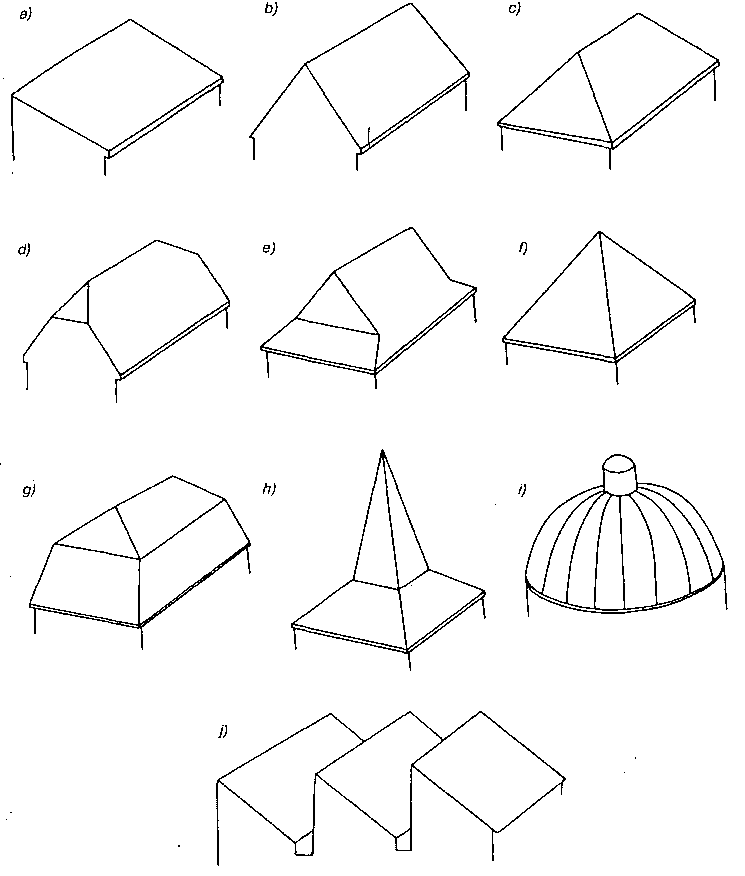

W rozwiązaniach ciesielskich stosowano przeważnie dachy strome, a to głównie ze względu na rodzaj użytego pokrycia — gonty, dachówka — jak również potrzebę wykorzystania przestrzeni poddasza na pomieszczenia mieszkalna lub gospodarcze. Najczęściej spotykane rodzaje dachów przedstawiono na rysunku.

Kształty dachów: a) jednopołaciowy, b) dwupołaciowy, c) czteropołaciowy, d) z półszczytem dolnym, e) z półszczytem górnym, f) namiotowy, g) mansardowy, h) wieżowy, i) kopulasty, j) pilasty.

Kształty dachów: a) jednopołaciowy, b) dwupołaciowy, c) czteropołaciowy, d) z półszczytem dolnym, e) z półszczytem górnym, f) namiotowy, g) mansardowy, h) wieżowy, i) kopulasty, j) pilasty.

Inżynierskie konstrukcje drewniane są stosowane głównie w budynkach jednokondygnacyjnych typu halowego o dużych rozstawach ścian lub slupów, Ten rodzaj budynków występuje w budownictwie przemysłowym (jako hale produkcyjne i magazynowe), sportowym i innym. Konstrukcje te mogą stanowić ustroje nośne budynków, lub tylko ich przekrycia. Kształty dachów są płaskie, strome łukowe itp.

Budynki i konstrukcje drewniane wykonuje się przeważnie z drewna iglastego: sosna, jodła i świerk. Dąb jako budulec używany jest na pale fundamentowe, podwaliny, progi, słupy i na elementy nośne w konstrukcjach szkieletowych (ryglowo-słupowych). Inne rodzaje drewna, jak: jesion, buk, grab, modrzew znajdują obecnie zastosowanie do robót wykończeniowych wewnętrznych.

Drewno przed wbudowaniem poddawane jest wstępnej obróbce, do której zalicza się: cięcie poprzeczne na odpowiednie długości, ociosywanie, łupanie lub piłowanie podłużne, wykonanie zaciosów i połączeń.

Drewno otrzymane przez piłowanie podłużne pni drewnianych, tzw. tarcie, stosowane jest powszechnie zarówno w budownictwie ciesielskim, jak i w konstrukcjach inżynierskich. Zgodnie z PN-75/D-010001 tarcicę dzieli się na: deseczki o grubości do 13 mm, deski, bale, listwy, łaty, krawędziaki i belki.