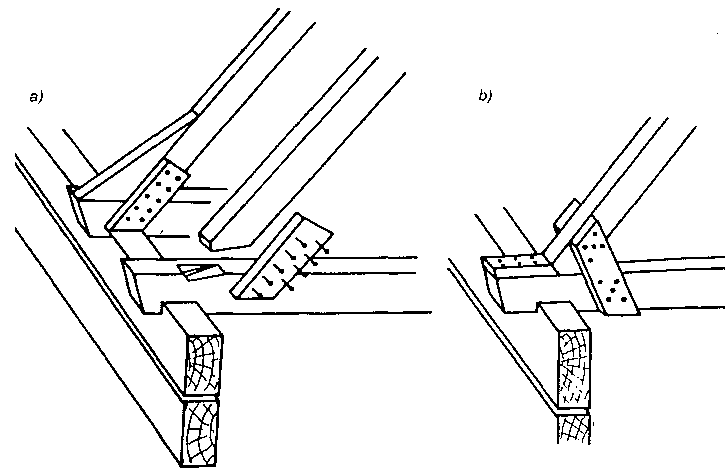

Złącza ciesielskie są pracochłonne i wymagają starannej robocizny, a czynnikiem decydującym o jakości złącza był odpowiednio dobrany zacios dostosowany do kierunku działania siły i profilu drewna. Rozróżnia się następujące rodzaje złącz ciesielskich:

a) wzdłużne poziome stosowane w podwalinach, oczepach, podciągach i legatach,

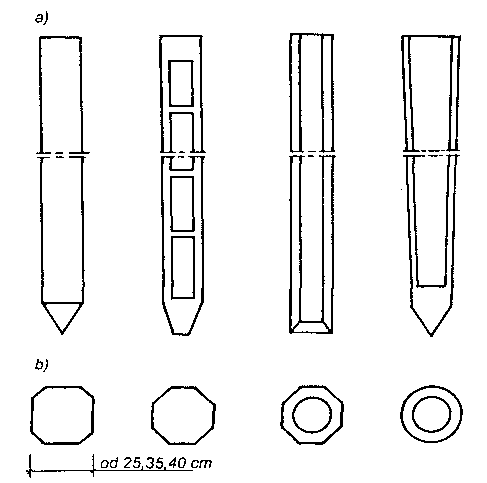

b) wzdłużne pionowe stosowane przy przedłużaniu słupów, pali i stojaków,

c) poprzeczne w połączeniu dwóch elementów ustawionych prostopadle lub ukośnie względem siebie, występujące w więźbie dachowej, w ścianach szkieletowych itp.,

d) narożne ścian wieńcowych, podwalin, oczepów, płatwi itp.,

e) na wrąb czołowy w wiązaniach dachowych.

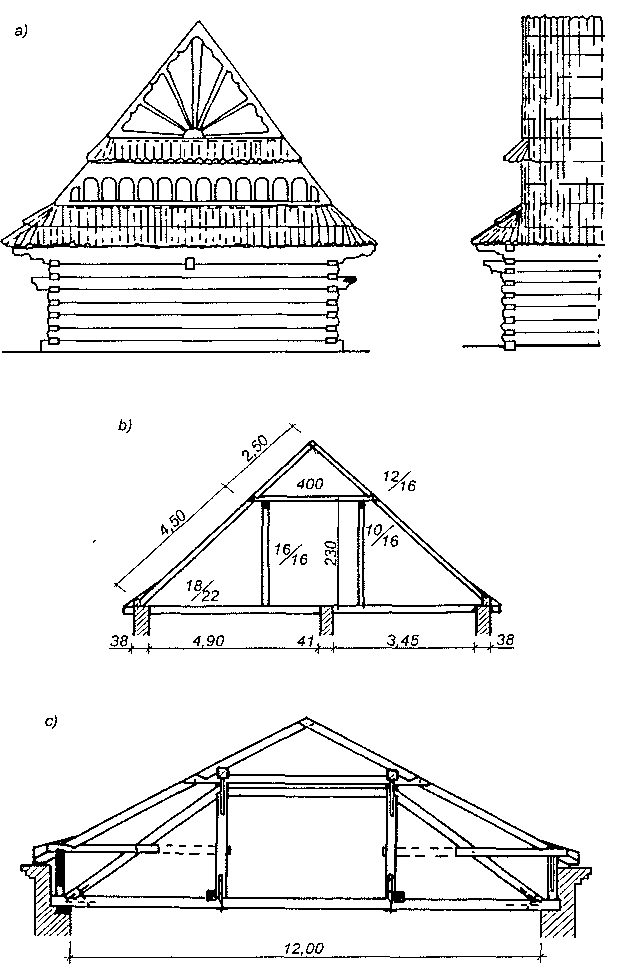

Rozwój kształtowania konstrukcji drewnianych odbywał się pod wpływem wielu czynników, a w szczególności rodzaju i dostępności budulca oraz narzędzi, przeznaczenia budowli, zapotrzebowania na budownictwo itp. W miarę doskonalenia rozwiązań konstrukcyjnych wzrastała rozpiętość przekryć budynków, podpory — ściany, słupy — rozstawiano coraz dalej, a budynek zyskiwał na lekkości.

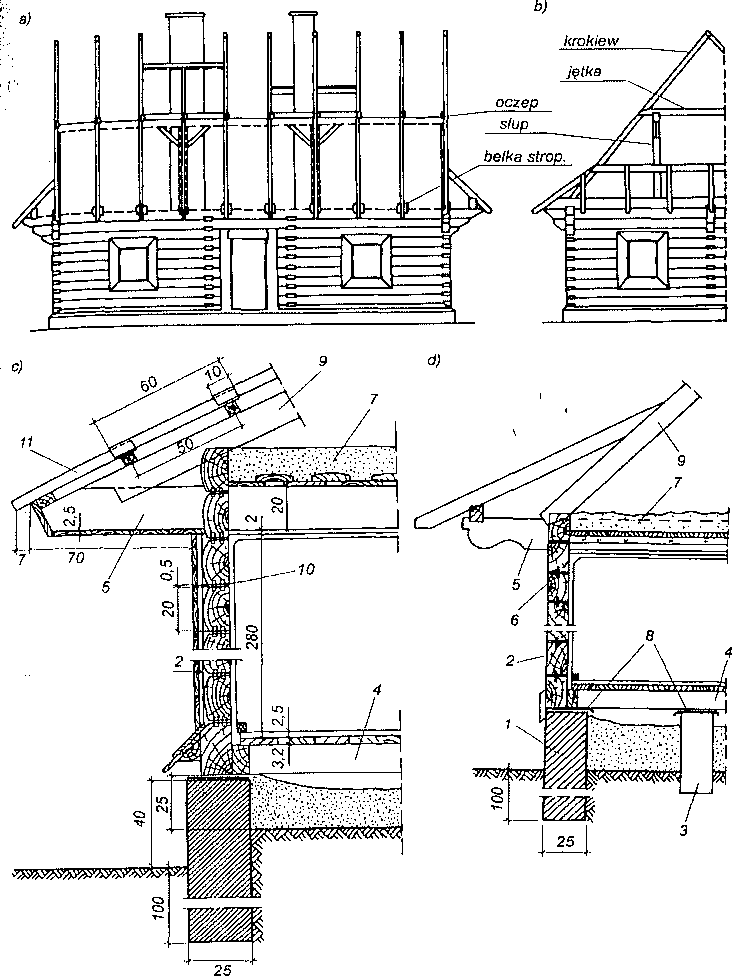

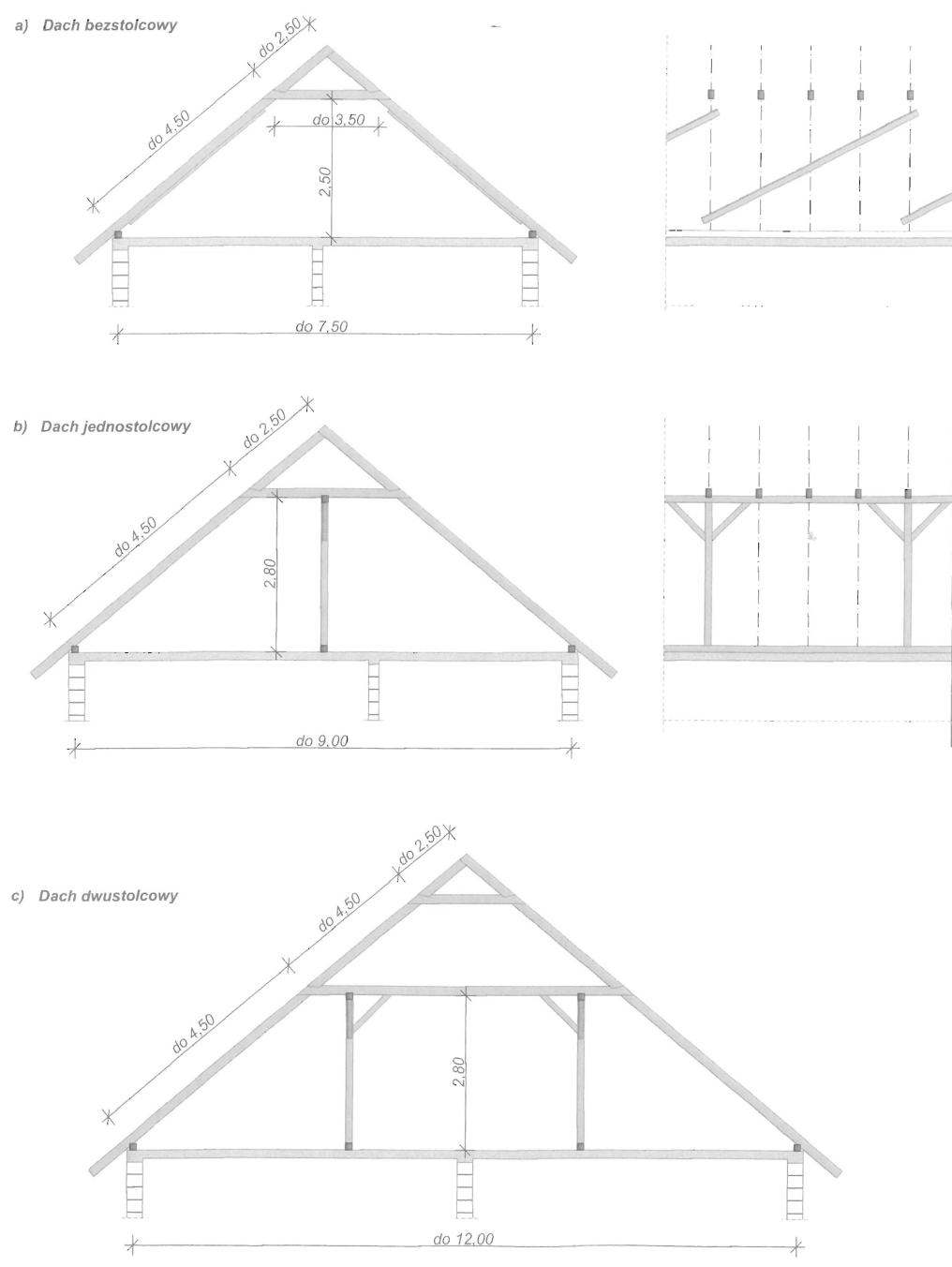

Konstrukcje ciesielskie: a) szczyt chałupy podhalańskiej, b) dach dwuspadowy jętkowy, c) wiązar dachowy dwuwieszakowy.

Konstrukcje ciesielskie: a) szczyt chałupy podhalańskiej, b) dach dwuspadowy jętkowy, c) wiązar dachowy dwuwieszakowy.

Na rysunku przedstawiono konstrukcje ciesielskie dachów w nawiązaniu do rozpiętości przekryć.

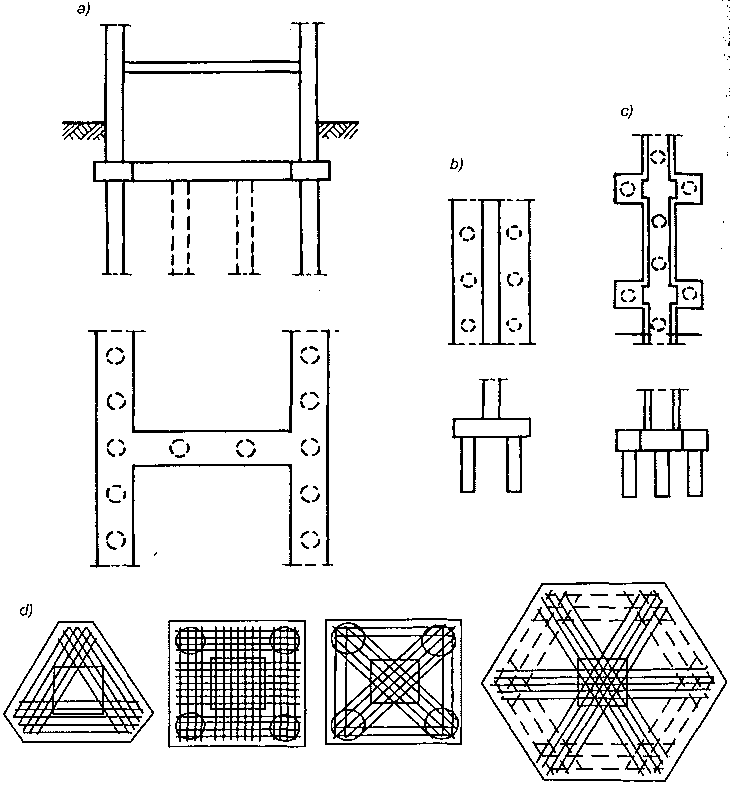

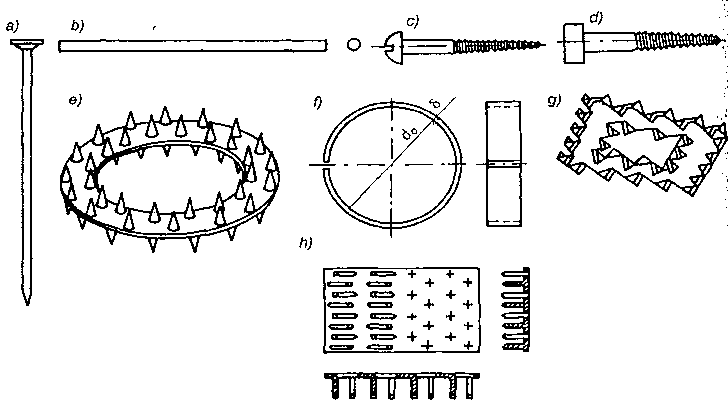

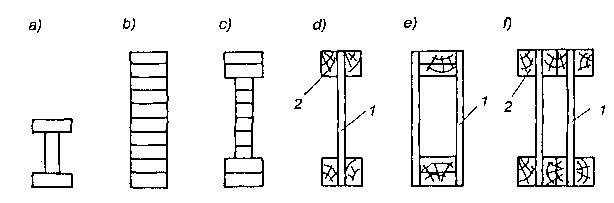

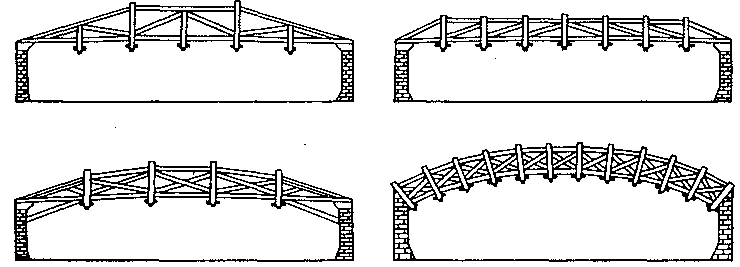

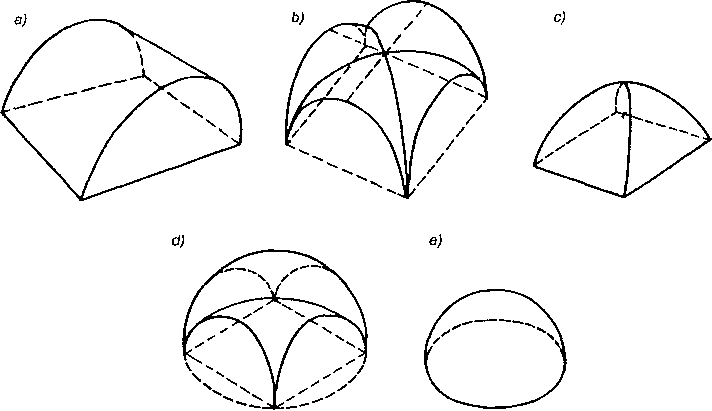

Pod koniec XIX w. następuje postęp w kształtowaniu konstrukcji drewnianych związany z zastosowaniem innych od ciesielskich połączeń elementów drewnianych, do których użyto łączników stalowych: gwoździ, sworzni, śrub, wkrętów i pierścieni. Oprócz belek o pełnym przekroju prostokątnym lub dwuteowym, zaczęto stosować belki oszczędnościowe w postaci kratownic. Zamiast typowych wiązarów ciesielskich zastosowano wiązary kratownicowe, łukowe, ramowe, sklepienia siatkowe itp. Do wykonania tych konstrukcji używa się krawędziaków, bali i desek o różnej szerokości i grubości.

W związku z ograniczonymi zasobami drewna i braku drewna o dużych przekrojach wprowadzono do budownictwa konstrukcje klejone drewniane oraz z materiałów drewnopochodnych.