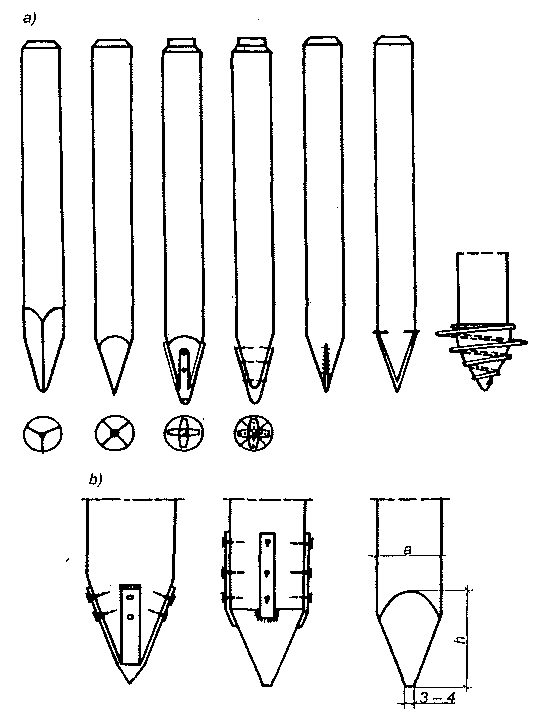

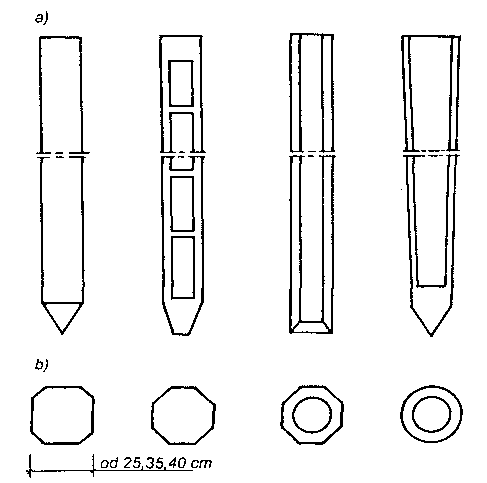

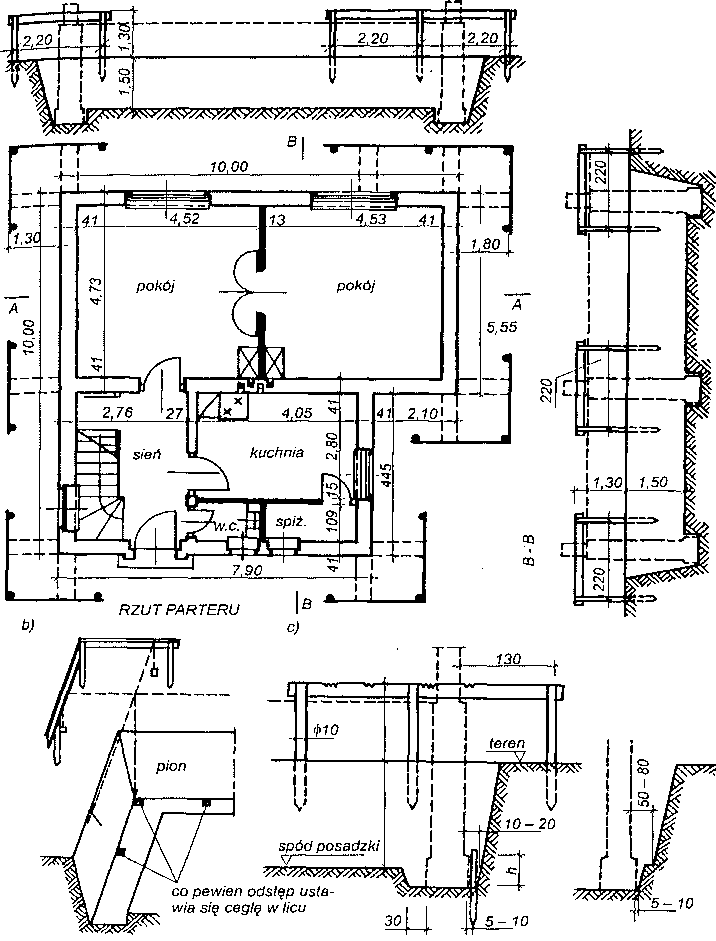

Na rysunku przedstawiono konstrukcję ścianki szczelnej, drewnianej składającej się z pali kierujących, bali wbijanych i kleszczy. Pale kierujące oraz wszystkie bale mają podłużne wycięcia pozwalające na osiągnięcie jednej płaszczyzny ścianki oraz większej szczelności.

Na rysunku przedstawiono konstrukcję ścianki szczelnej, drewnianej składającej się z pali kierujących, bali wbijanych i kleszczy. Pale kierujące oraz wszystkie bale mają podłużne wycięcia pozwalające na osiągnięcie jednej płaszczyzny ścianki oraz większej szczelności.

Bale są na dolnym końcu ścięte pod kątem 10-30°, co powoduje, że podczas ich wbijania są mocniej dociskane do siebie.

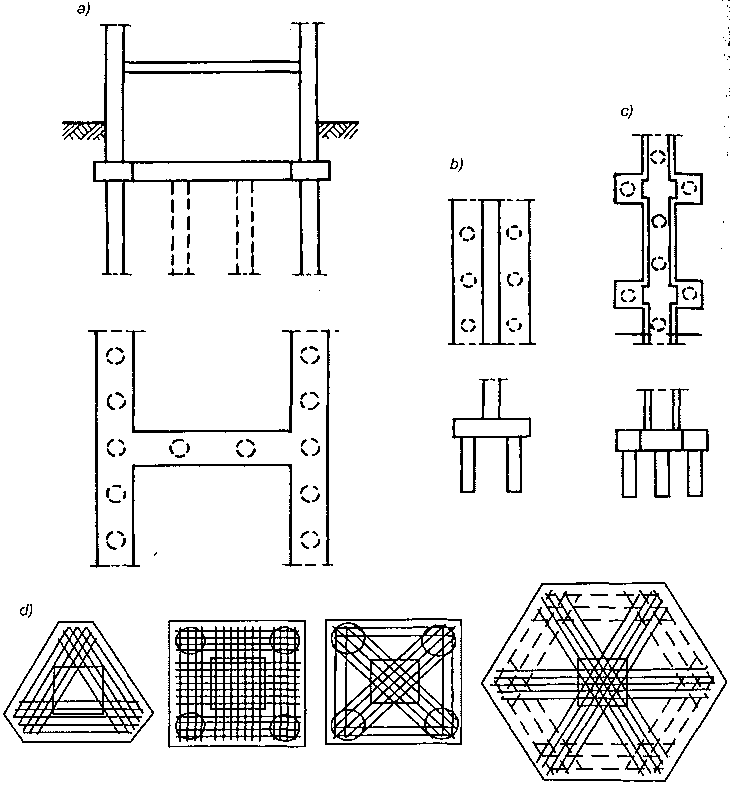

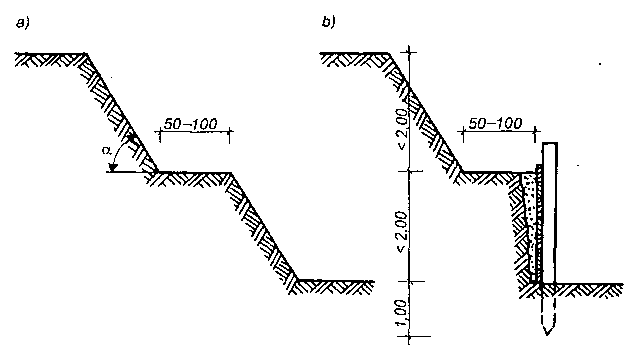

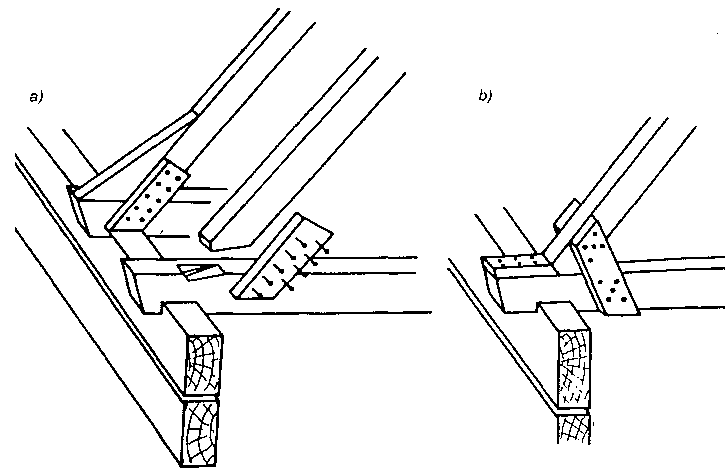

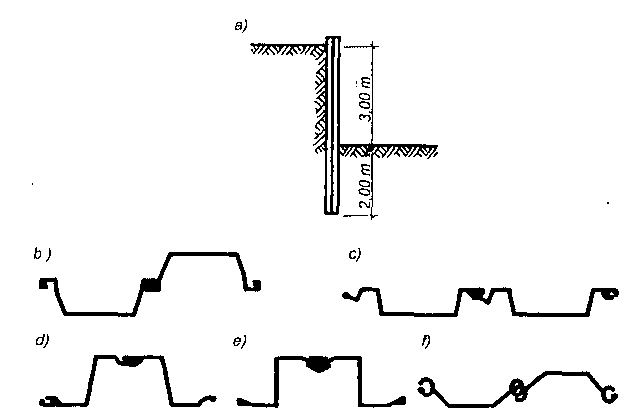

Przy głębokościach wykopów powyżej 3,0-5,0 m występuje duże parcie ziemi i wody i wówczas zachodzi konieczność stosowania ściany szczelnej stalowej. Ściany te wykonywane są z różnych profili wytwarzanych przez huty. W Polsce szeroko stosowany jest niemiecki typ Larssena (rys.b) o szerokości 400 mm i wysokości 247-290 mm.

Podparcie ścian wykopu za pomocą ścian szczelnych stalowych: a) przekrój przez ściankę, b), c), d), e), 0 przekroje stosowanych profili stalowych.

Podparcie ścian wykopu za pomocą ścian szczelnych stalowych: a) przekrój przez ściankę, b), c), d), e), 0 przekroje stosowanych profili stalowych.

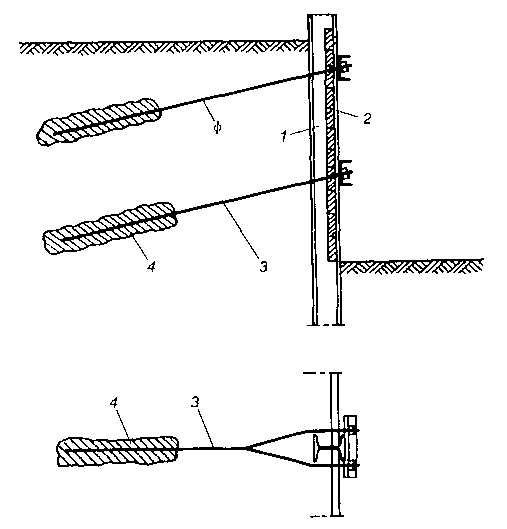

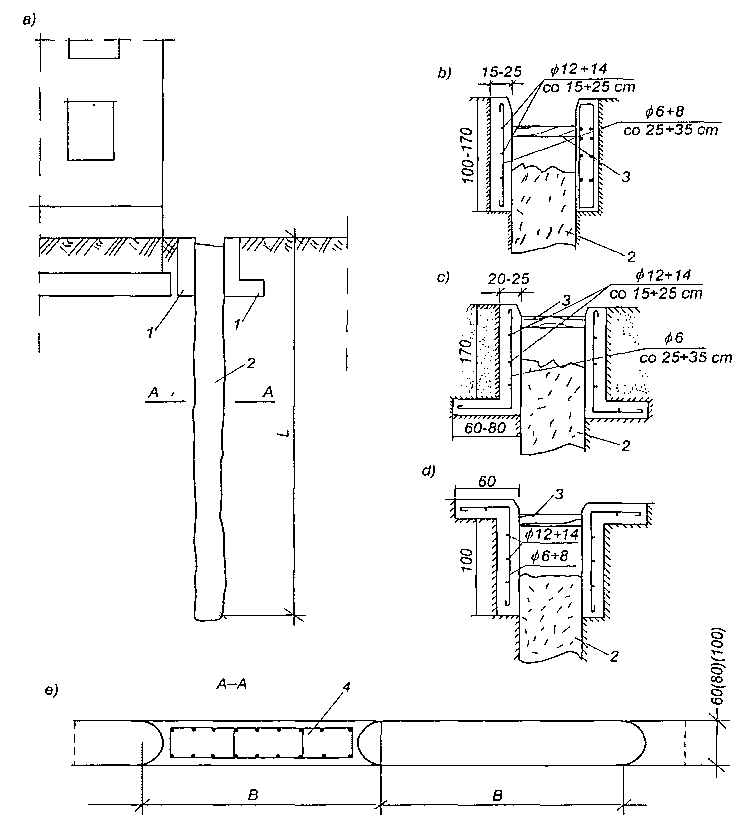

Szeroko stosowanym sposobem zabezpieczenia ścian wykopów szerokoprzestrzennych i głębokich na działkach budowlanych o małej powierzchni oraz w bezpośrednim sąsiedztwie z istniejącymi budynkami, są ściany szczelinowe z betonu w gruncie.

Ściany szczelinowe wykonuje się na obwodzie projektowanego wykopu odcinkami o długości od 2,5 do 10,0 m i głębokości do 50,0 m.

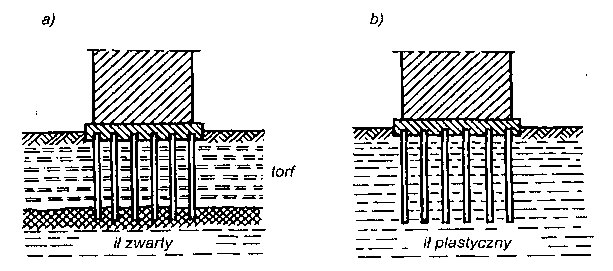

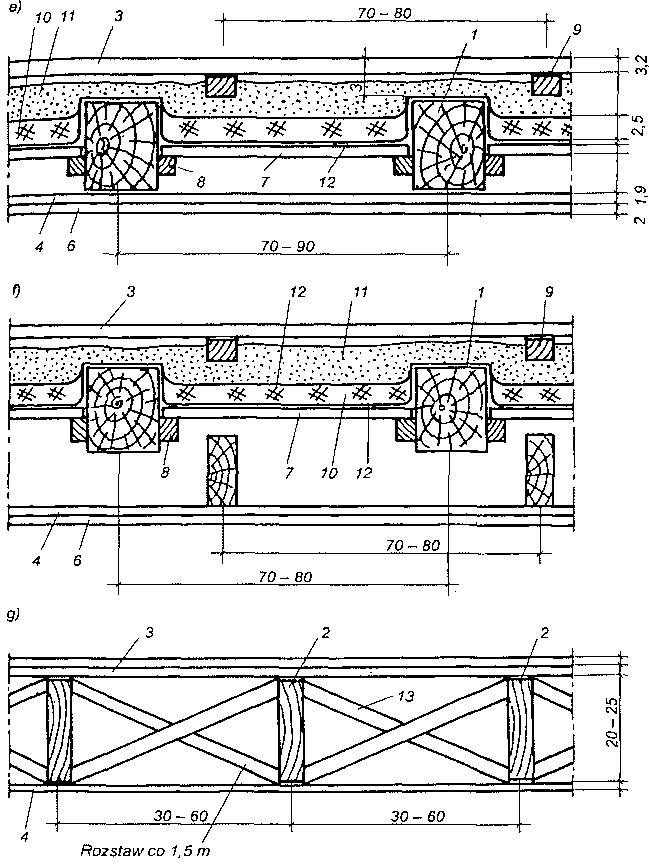

Żelbetowa ściana szczelinowa zabezpieczająca wykop: a) przekrój poprzeczny, b), c), d) przekroje poprzeczne ścianek prowadzących, e) przekrój poziomy ściany; 1 — ścianki prowadzące, 2 — ściana w gruncie, 3 — rozpórka, 4 — zbrojenie.

Żelbetowa ściana szczelinowa zabezpieczająca wykop: a) przekrój poprzeczny, b), c), d) przekroje poprzeczne ścianek prowadzących, e) przekrój poziomy ściany; 1 — ścianki prowadzące, 2 — ściana w gruncie, 3 — rozpórka, 4 — zbrojenie.

Ściany szczelinowe betonowe mogą być stosowane w każdym gruncie niezależnie od jego spoistości i poziomu położenia zwierciadła wody gruntowej.

Szczeliny w gruncie wykonuje się koparkami o zadanej szerokości czerpaka, który wprowadzany jest w grunt między ścianki prowadzące (rys.d, c, d). Ścianki prowadzące nadają czerpakowi właściwe położenie w gruncie podczas głębienia wykopu. W trakcie wybierania ziemi i pogłębiania szczeliny do wykopu wlewa się zawiesinę o właściwościach tiksotropowych, np. bentonit, który wywiera parcie na ściany szczeliny i utrzymuje grunt w stanie równowagi.

Po wykonaniu szczeliny w gruncie na żądaną głębokość — wypełnioną bentonitem — wstawia się na jej końcach rury stalowe zwane stopowymi lub inne profile stalowe, które kończą szczelinę i kształtują złącze między poszczególnymi segmentami ściany. Pomiędzy rurami „stopowymi” ustawia się — w bentonicie — szkielety zbrojenia o wymaganym polu przekroju prętów, a następnie przystępuje do betonowania, zaczynając wypełnienie mieszanką betonową od dna wykopu za pomocą rury zasilającej, która w miarę postępu betonowania podciągana jest do góry. Wypierany przez mieszankę betonową bentonit jest usuwany ze szczeliny i może być ponownie użyty przy wykonaniu następnego segmentu ściany. Następny segment powinien być wykonywany w co drugim polu sąsiadującym, a wykonanym wcześniej segmentem.

Po wykonaniu dwóch segmentów można dopiero przystąpić do wykonania szczeliny segmentu między nimi, a po usunięciu ziemi i wypełnieniu bentonitem usuwa się rury „stopowe”, ustawia szkielety zbrojenia i betonuje.