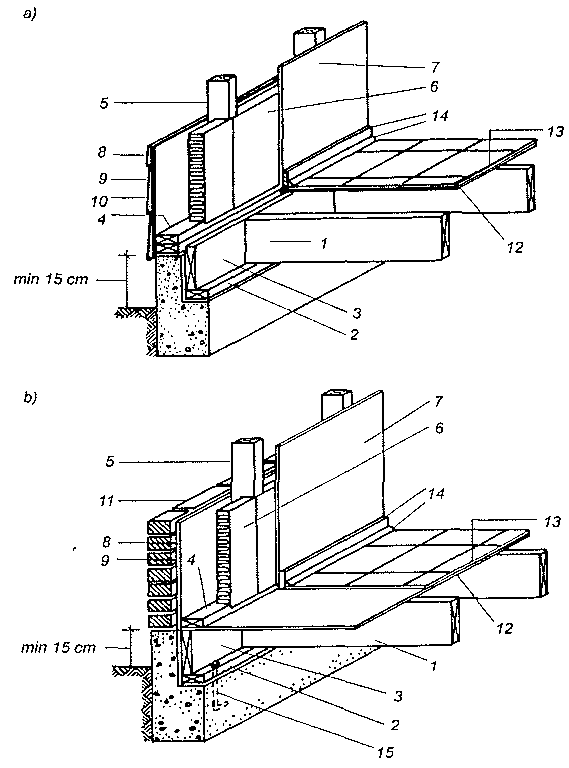

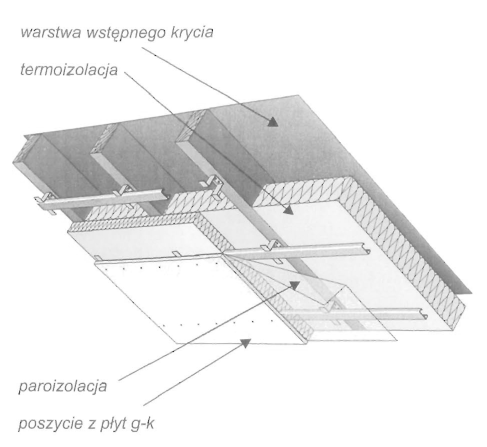

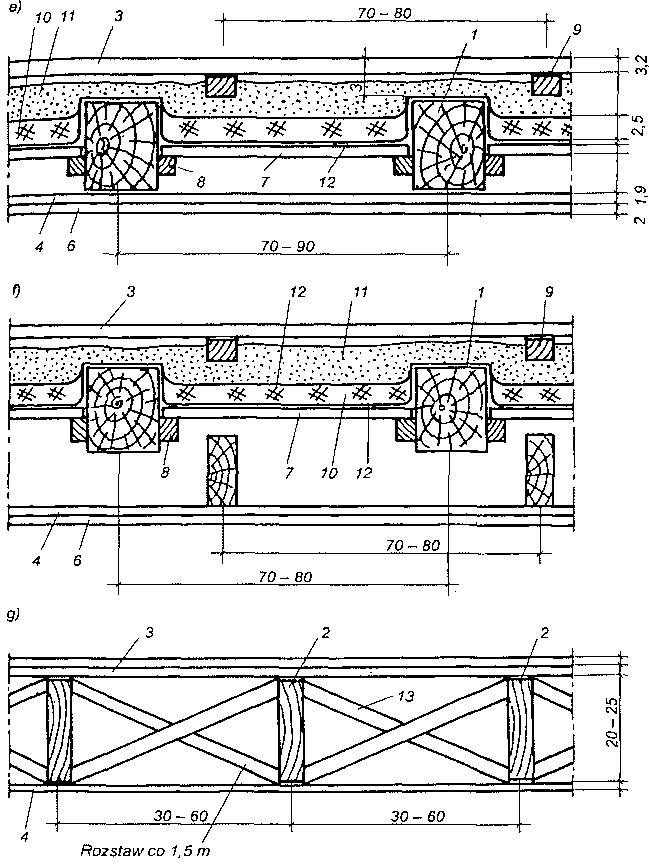

Często zdarza się, że istniejąca w starych budynkach izolacja pomiędzy łatami nie zapewnia dostatecznej izolacji termicznej ze względu na zbyt małą głębokość przestrzeni pomiędzy krokwiami. Zwiększając grubość izolacji od strony pomieszczeń, traci się na wysokości. Jeżeli istnieje konieczność wymiany pokrycia dachowego, wtedy można wykorzystać okazję i założyć dodatkową izolację na krokwiach. Tutaj zastosowano płytę z włókna drzewnego o współczynniku przewodzenia ciepła 045. Po założeniu folii chroniącej przed wiatrem i wilgocią zewnętrzną, uzyskuje się szczelną warstwę izolacyjną. Płyty łączone są na pióro i wpust.

Jeżeli konstrukcja dachu i jego pokrycie są nieuszkodzone, wtedy dodatkowa izolacja na krokwiach ma sens, pod warunkiem, że nie jest ona związana ze zbyt dużym nakładem. Przedstawiony tu system przeznaczony jest do tego typu przypadków. Łaty dachowe pozostają nienaruszone, zdejmuje się jedynie dachówki i od razu zakłada izolację. Pracę zaczyna się od prawej ściany szczytowej i po zdjęciu dachówek z niewielkiej części dachu, zawiesza się na łatach małe płyty ze styroporu, które nachodzą na siebie w sposób łuskowały. Zaraz potem można ponownie mocować dachówki.

Prace remontowe dachu stanowią poważne utrudnienie w życiu codziennym mieszkańców budynku. Inaczej sprawa wygląda, jeżeli roboty prowadzone są z zewnątrz. Warunkiem jest dobry stan techniczny konstrukcji dachu, który umożliwia położenie bezpośrednio na łatach wielkoformatowych, lekkich płyt izolacyjnych. Duży wymiar (1×2,4m) oraz łączenie na pióro i wpust umożliwiają szybkie wykonanie pracy. Przedstawione płyty pokryte są od dołu folią aluminiową, a na górze materiałem bitumicznym. Płyty mocowane są do krokwi kontrłatami.

Zdarza się, że nie można wykonać izolacji zewnętrznej na starych budynkach, ponieważ nie wolno przekroczyć dozwolonej wysokości domu. Wyjściem z sytuacji jest system izolacji przedstawiony przez firmę Maco Dach. Składa się on z warstwy wiatrochronnej, oszalowania i izolacji. Także w tym przypadku prace można wykonywać równolegle., tzn. stopniowo zdejmując stare dachówki i mocując od razu docieplenie. W tym celu zakłada się najpierw folię na odsłoniętych łatach i mocuje ją do drewna zszywaczem. Następnie nakłada się płyty z włókna drzewnego lub utwardzonej pianki, które nie wchłaniają wody i wilgoci. Potem mocuje się już tylko dachówki.

Obok tradycyjnej dachówki bardzo popularne są pokrycia dachowe z blachy, wykonanej ze stali ocynkowanej, aluminium lub miedzi. Do mocowania tych materiałów konieczne jest wykonanie deskowania, stanowiącego podkład. Ciekawe rozwiązanie przedstawia tutaj firma IsoBouw – jej system bazuje na płycie warstwowej, wypełnionej polistyrenem piankowym. Jej górną warstwę stanowi płyta OSB, która sprawia, że elementy są samonośne i stanowią dobry podkład do mocowania poszycia dachowego. Elementy izolacyjne układane są na deskowaniu pokrytym materiałem bitumicznym, chroniącym przed wilgocią z wnętrza budynku. Na górze również zakładana jest folia ochronna.

Dachy o zaokrąglonym kształcie znajdują powoli zwolenników także wśród inwestorów indywidualnych. Wykonanie prawidłowej termoizolacji w tych warunkach nastręczało do tej pory sporo trudności. Problem przestał istnieć z chwilą pojawienia się elementów termoizolacyjnych wykonanych z utwardzonej pianki poliuretanowej, które posiadają specjalną, rowkowaną nawierzchnię. Dzięki temu dopasowują się one łatwo do zaokrąglonej powierzchni i ściśle do niej przylegają. Materiał izolacyjny chroniony jest od spodu przez warstwę parochronną, potem mocuje się kontrłaty, deskowanie i folię wiatro- i wodoszczelną.