Alternatywą dla lekkiego szkieletu drewnianego są budynki wykonywane w technologii szkieletu stalowego.

Stal jako materiał konstrukcyjny używany do budowy domów jest w porównaniu z drewnem materiałem względnie tanim i łatwym do pozyskania. Odznacza się stałymi właściwościami technologicznymi i mechanicznymi oraz możliwością dokładnego określenia parametrów technicznych. Wysoka wytrzymałość stali pozwala na oszczędności, jak np. przy projektowaniu stropów o dużej rozpiętości bez konieczności stosowania podpór pośrednich.

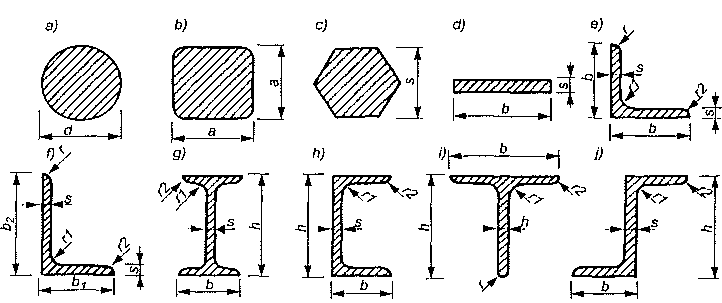

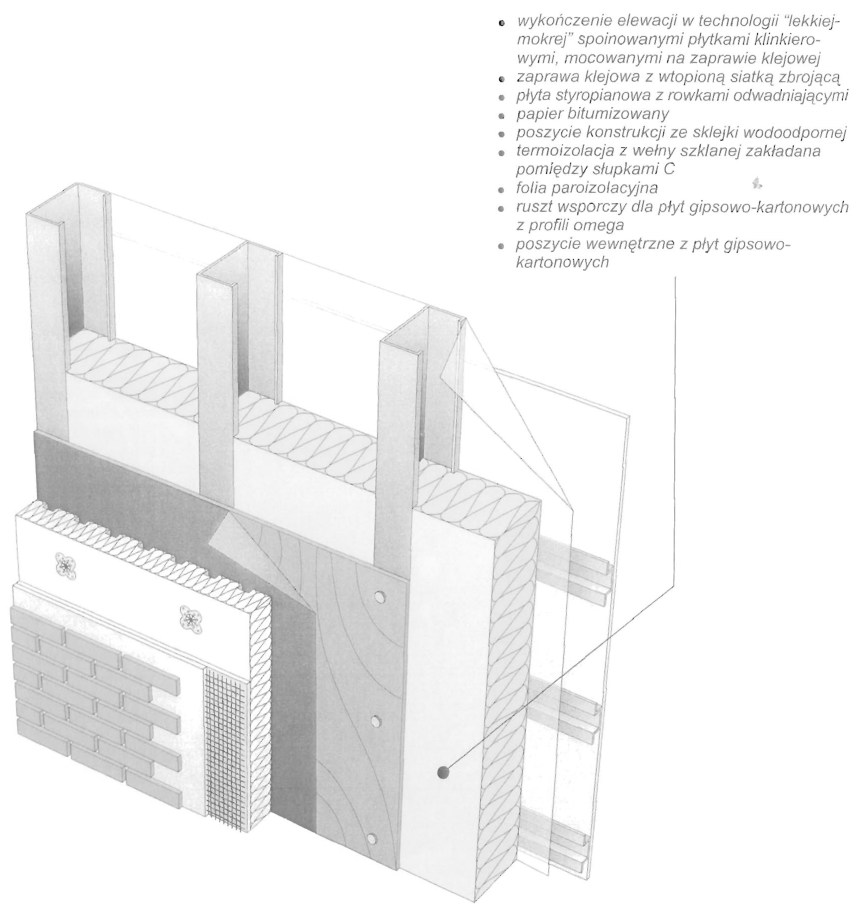

Nowoczesne konstrukcje szkieletowe ze stali wykonywane są z zimno-giętych, cienkościennych profili produkowanych z taśm blachy ocynkowanej. Do produkcji stosowana jest blacha o grubości 0,5-2 mm walcowana na zimno.

Kształtowniki walcowane na gorąco (np. dwuteowniki) stosowane są w konstrukcjach szkieletowych coraz rzadziej, przede wszystkim ze względu na duży ciężar i koszty

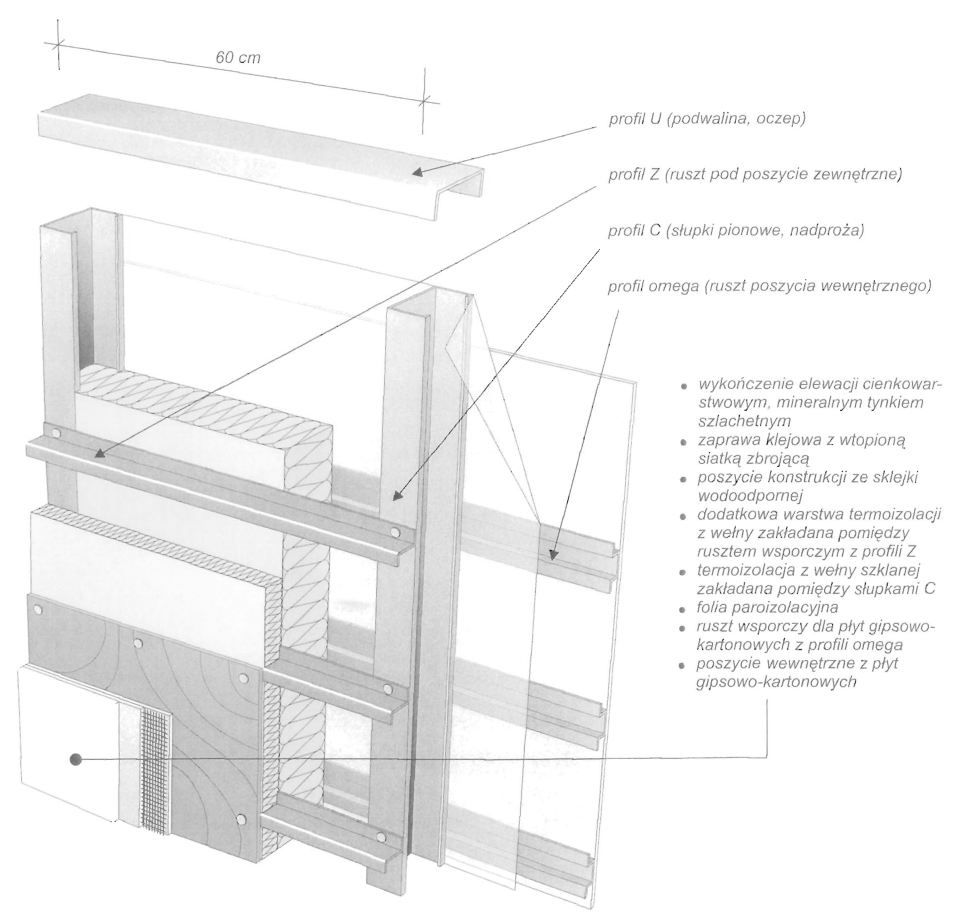

Konstrukcja stalowa oparta jest na podobnych zasadach jak konstrukcja w budynkach szkieletowych z drewna.

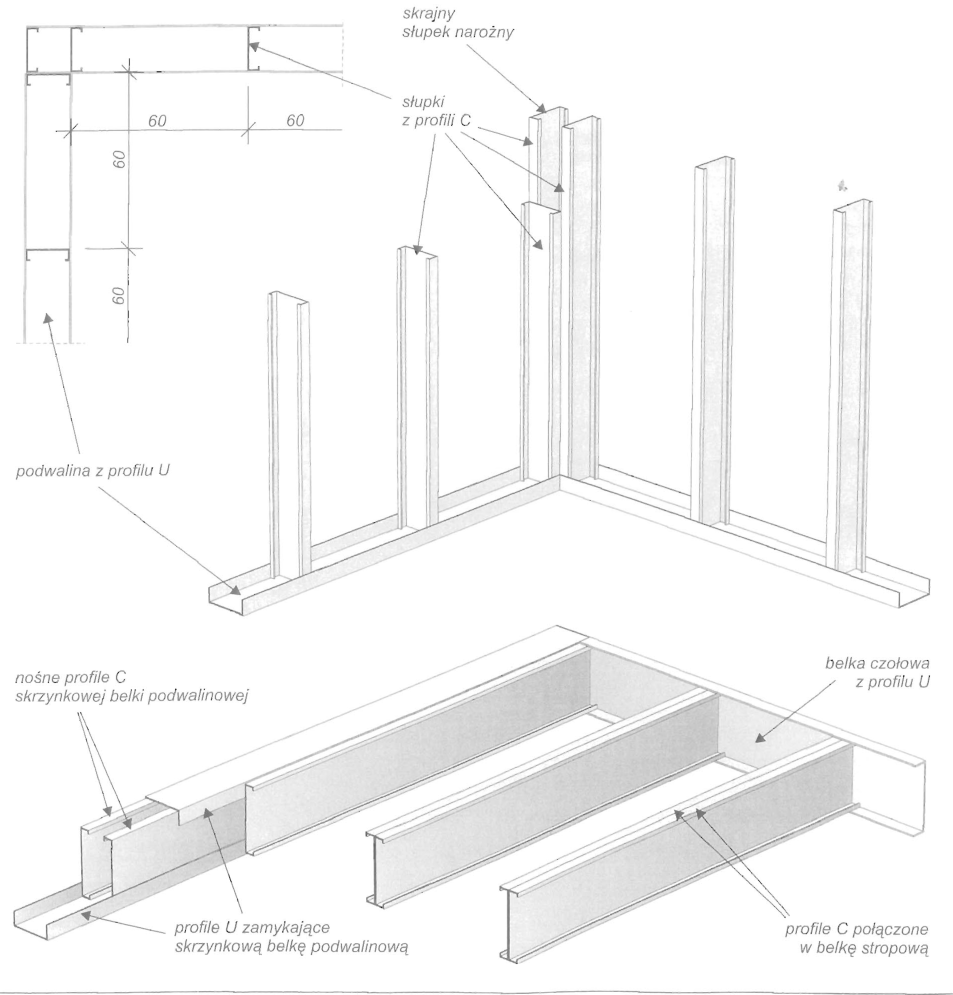

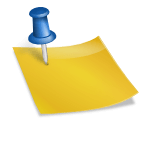

Rozstaw słupów w szkielecie stalowym wynosi 60 cm. Słupy wykonane są z profili stalowych C i zamocowane u dołu w prowadnicy wykonanej z profilu U, która jest odpowiednikiem drewnianej podwaliny. Konstrukcja stalowa jest często dodatkowo usztywniana ukośnymi prętami. Poziome usztywnienia zabezpieczają słupy przed wyboczeniem i ewentualną utratą stateczności. Od góry stężenie pionowych słupów stanowi belka oczepowa z odwróconego profilu U – nałożonego na słupy. Usztywnieniem szkieletu jest poszycie zewnętrzne ze sklejki lub wiórowej płyty wodoodpornej.

Konstrukcja stalowa wykonywana jest na zabezpieczonych pasami papy ścianach fundamentowych, wyprowadzonych ponad teren na min. 30 cm. Szkielet budynku może być częściowo montowany w wytwórni. Prefabrykowane elementy konstrukcji, takie jak dźwigary dachowe, elementy stropów i gotowe elementy ścienne, przewożone są na plac budowy i montowane w całość.

Gdy montaż szkieletu odbywa się na budowie, słupy i belki są najpierw łączone w elementy ścienne, po czym podnoszone i ustawiane w wyznaczonych miejscach na płycie fundamentu.

Szkielet mocuje się do fundamentu śrubami wstrzeliwanymi gwoździami i taśmami kotwiącymi. Poszczególne elementy szkieletu łączy się wkrętami samonawiercającymi.

Po ustawieniu i skręceniu ścian mocowane jest poszycie zewnętrzne ze sklejki lub wodoodpornych płyt wiórowych. Poszycie stęża wszystkie elementy konstrukcji w całość.

Następnym etapem budowy jest montaż stropów i dźwigarów dachowych. Stropy wykonuje się z belek C. W budynkach piętrowych pod oparciami belek stropowych oraz pomiędzy belkami stropowymi a poszyciem, powinny być założone paski filcowe, które pozwalają zminimalizować zjawisko przenoszenia drgań.

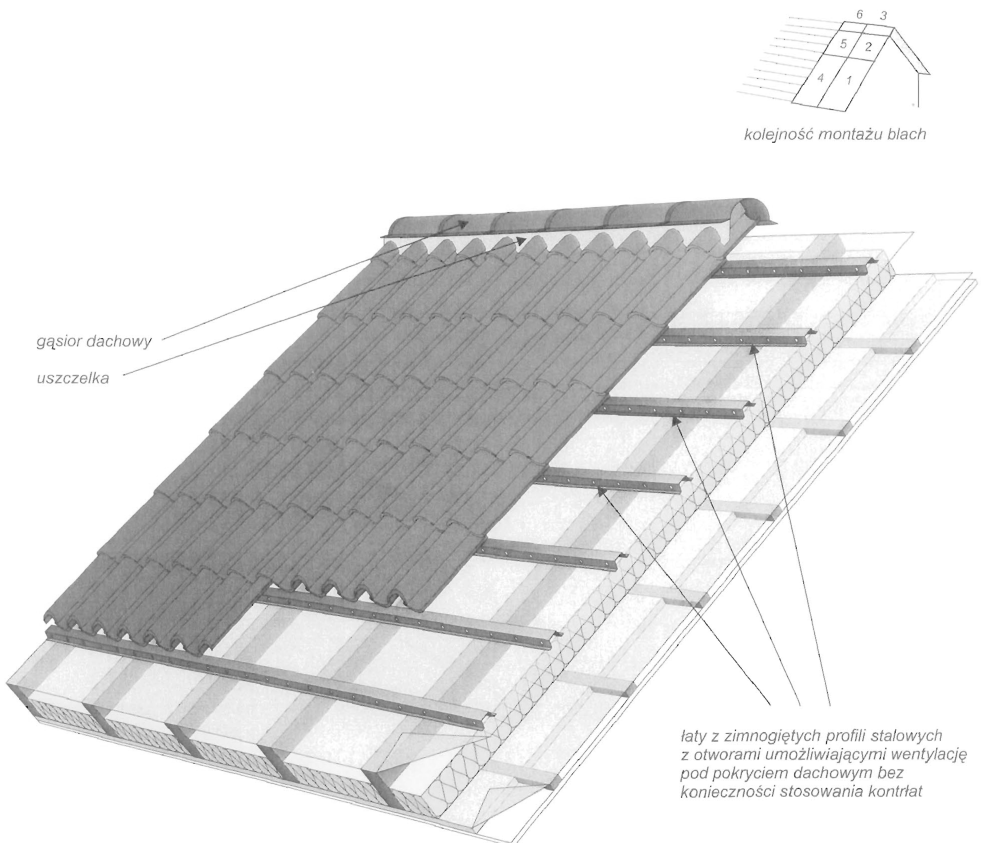

Dźwigary dachowe składa się z zaprojektowanych profili i opiera na ścianach budynku. Ich elementy łączone są tak, jak elementy ścian zewnętrznych. Dźwigary o dużych rozpiętościach mogą mieć węzły obustronnie usztywnione blachą.

Na stropach i dachu, podobnie jak na ścianach zewnętrznych, mocowane jest stężające poszycie ze sklejki lub wodoodpornych płyt wiórowych.

Domy szkieletowe w konstrukcji stalowej mogą mieć do 3 kondygnacji wysokości. Dobór odpowiednich profili na wszystkie elementy budynku wymaga szczegółowych obliczeń konstrukcyjnych.