Pale wykonywane w gruncie.

Pale tego rodzaju mogą być bez trudu wykonywane ściśle do potrzebnej długości, po stwierdzeniu rzeczywistego oporu gruntu ustalanego podczas nabijania pali. Jest to ich duża zaleta, gdyż ewentualne błędy powstałe przy wstępnej ocenie gruntu mogą być naprawione. Tego rodzaju korekty nie można przeprowadzić, w palach omawianych poprzednio.

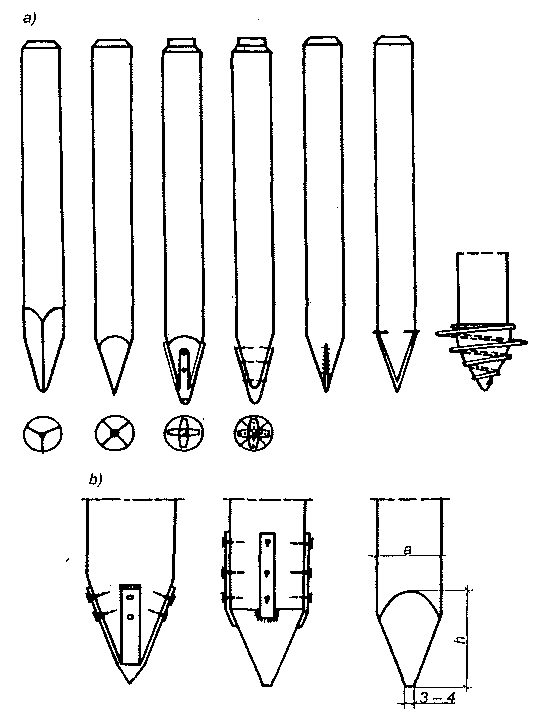

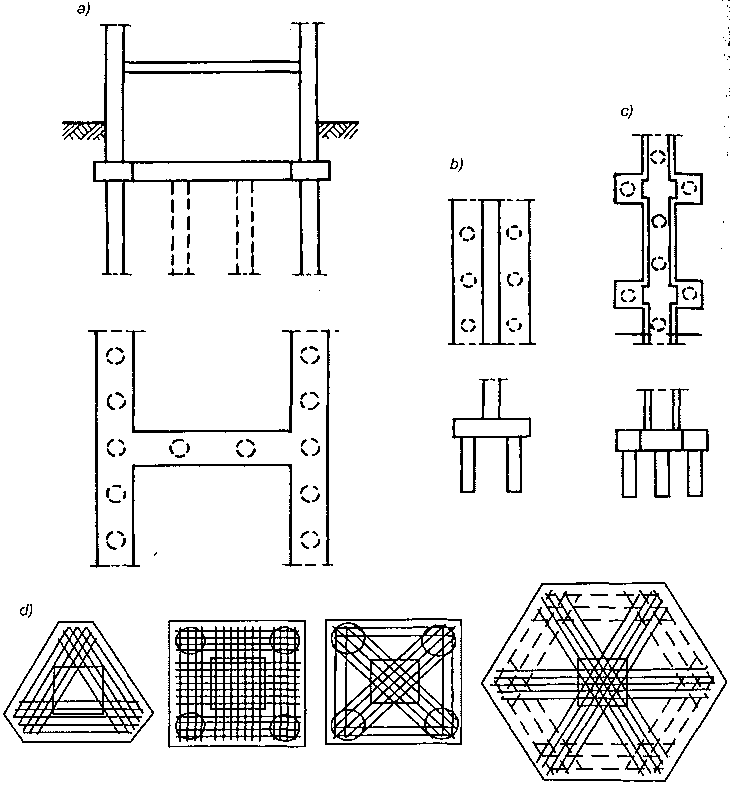

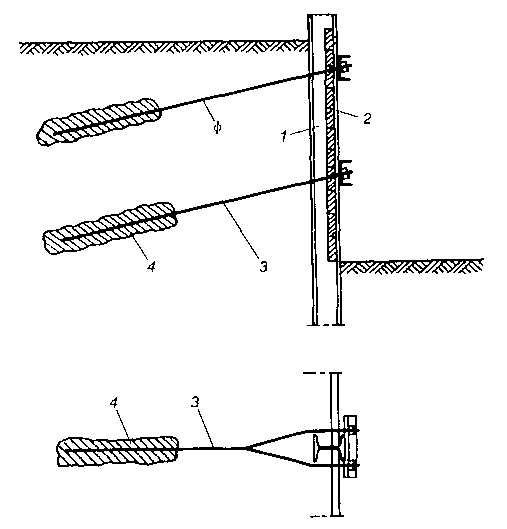

Pale nabijane wykonuje się od razu na miejscu budowy w miejscu ich przeznaczenia, w gruncie pod osłoną zapuszczonej uprzednio rury obsadowej lub też bez tej osłony w wykonywanym otworze.

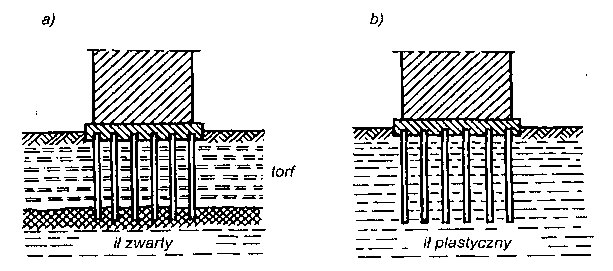

Rury obsadowe mogą być „odzyskane”, tj. wyciągane z gruntu w miarę wykonywania pali. Jeśli pale wykonywane są w gruntach nawodnionych, a woda jest szkodliwa dla betonu, osłona pozostaje na stałe z palami.

Beton w osłonie lub gruncie jest zwykle zagęszczany przez stosowanie ubijania, wibrowania lub pneumatycznie. Coraz rzadziej wykonuje się pale z betonu niezagęszczonego.

Do grupy pali wykonywanych w gruncie można zaliczyć: pale Franki, pale Straussa i pale Wolfsholza.

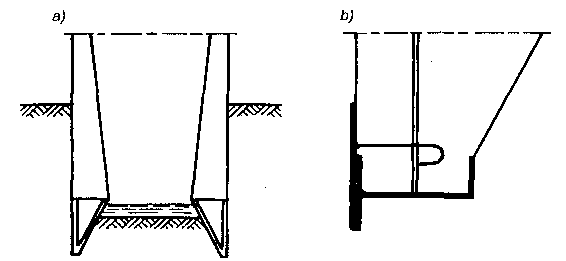

Pale Franki. Wykonanie pala Franki polega na wbiciu w grunt za pomocą kafara stalowej rury obsadowej o średnicy wewnętrznej 400-600 mm, grubości ścianki 20-30 mm. W dolnym końcu rury wykonuje się korek, zamykający wnętrze rury, który chroni przed dostaniem się do wnętrza wody gruntowej, a ponadto wbijanie rury w grunt dokonywane jest przez uderzenie baby w korek.

Okres wykonania pali Franki jest nieco dłuższy od zagłębiania pali drewnianych czy prefabrykowanych, a beton pali ma dużą gęstość, jest szczelny i odporny na szkodliwe wpływy agresywnych składników wody gruntowej.

Przy wykonywaniu pali Franki i pali wbijanych powstają wstrząsy, które niekorzystnie oddziałują na sąsiednie budowle i urządzenia.

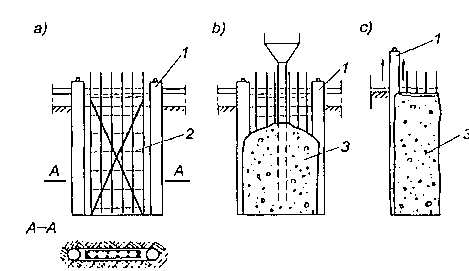

Pale wiercone. Do grupy pali wierconych zalicza się pale Straussa i pale Wolfsholza. Pale te wykonywane są w ten sposób, że rurę obsadową zagłębia się w gruncie sposobem wiertniczym, tj. z równoczesnym wydobywaniem gruntu z wnętrza rury, po czym wyciąga się ją stopniowo do góry i jednocześnie betonuje.

Pale Straussa i Wolfsholza mogą być stosowane w tych miejscach, gdzie wstrząsy mogłyby źle oddziaływać na otaczające budynki lub urządzenia. Przy wykonaniu ich wstrząsy praktycznie nie występują. Ponadto można je wykonywać w warunkach, gdy są ograniczone wymiary miejsca pracy.

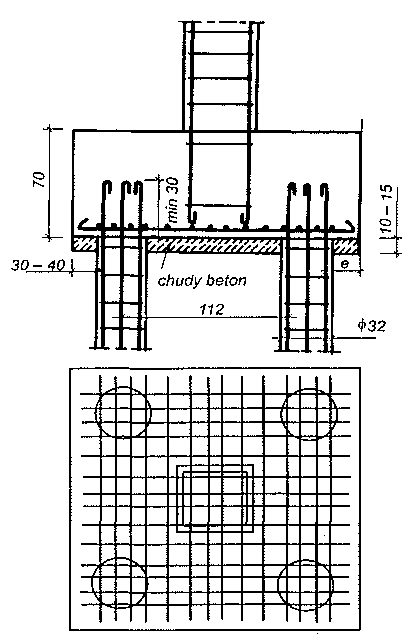

Po wykonaniu otworu pala Straussa do projektowanej głębokości, układa się w nim beton za pomocą pojemników z otwieranym dnem. Porcje betonu o wysokości ok. 70 cm ubija się lekkim ubijakiem i stopniowo wyciąga się rurę do góry, tak aby zawsze w rurze pozostawała warstwa betonu o wysokości co najmniej 30 cm.

Betonowanie pala Wolfsholza odbywa się po wyparciu wody z rury za pośrednictwem sprężonego powietrza o mniejszym ciśnieniu, doprowadza się beton pod nieco większym ciśnieniem, a następnie wpuszcza się powietrze pod wysokim ciśnieniem. Zwiększone ciśnienie zagęszcza beton i dociska go do gruntu, co wpływa w dużej mierze na zwiększenie nośności pali.