Fachowe układanie wykładzin dywanowych, PCV i parkietów może odbywać się wyłącznie na płaskich, suchych i czystych podłożach, których powierzchnia nie wykazuje zbytniej chłonności i nie jest porowata. Szczególnie ważne jest, aby przy naklejaniu wykładzin podłogowych różnica wysokości pomiędzy dwoma punktami o odległości 40 cm nie przekraczała 1 mm. Przy rozstawie punktów powierzchni rzędu 4 m są jeszcze akceptowalne różnice wysokości do 10 mm.

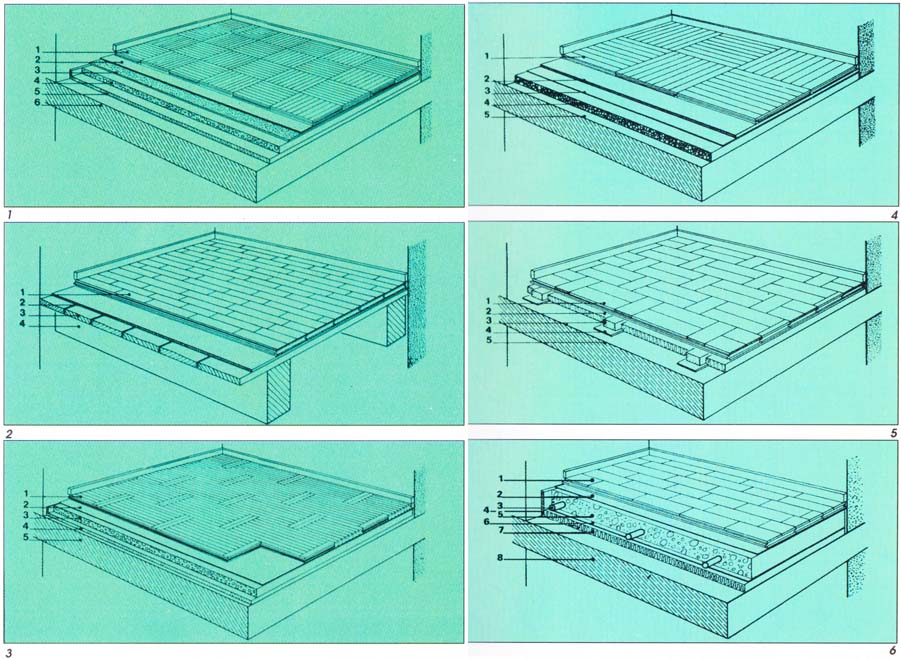

Posadzki betonowe i jastrychy cementowe wykazują często większe różnice wysokości. Gładzenie i wyrównywanie posadzek betonowych i jastrychów cementowych było zawsze ciężką, intensywną i czasochłonną sprawą. Od pewnego czasu są do tego celu tzw. “płynne jastrychy”, które zarobione wodą i wylane na posadzkę, rozpływają się samoczynnie i tworzą ścisłą, wytrzymałą na ściskanie i dokładnie płaską powierzchnię. Płynne jastrychy nadają się do układania wykładzin dywanowych, PCV i parkietu (naturalnie także do ceramicznych wykładzin podłogowych). Mogą być nakładane warstwami o grubości do 30 mm, można po nich chodzić po niecałym dniu i po mniej więcej tygodniu można na nich położyć wykładziny podłogowe.

Fachowiec radzi

Wpierw odbija się wszystkie wystające resztki zaprawy młotkiem i przecinakiem. Także warstwy kruche, stare powłoki malarskie i impregnacje należy usunąć zeszlifowaniem lub zeszczotkowaniem. Następnie podłogę należy dokładnie zamieść.

Zapotrzebowanie materiałowe

• Na pokrycia o wysokości 2 do 10 mm nie daje się do mieszaniny żadnych dodatków.

• Na wysokości warstw pomiędzy 10 a 20 mm do proszku, zarobionego wodą, dodaje się piasek o ziarnistości 0-4 mm. Stosunek mieszaniny wynosi 1 część proszku na 1 część piasku (części objętościowe).

• W wypadku pokryć o wysokości do 30 mm miesza się do proszku, rozprowadzonego wodą drobny żwir (ziarnistość 0-8 mm). Stosunek mieszaniny wynosi tutaj 1 część objętości proszku do 2 części objętości żwiru.

Przed nałożeniem płynnego jastrychu trzeba podłogę zagruntować. Na ogół wystarcza zagruntowanie polepszaczem zaprawy rozcieńczonej wodą. Również nie wolno zapomnieć o krawędziach powierzchni podłogi. Zanim płynny jastrych będzie mógł być nałożony zagruntowanie musi całkowicie wyschnąć.

Fachowiec radzi

W wypadku podłóg o silnej nasiąkliwości (przeprowadzić próbę zwilżenia!) konieczne jest naniesienie szlamu przyczepnego. W tym celu płynny jastrych przygotowuje się przez zarobienie wodą do konsystencji umożliwiającej smarowanie. Szlam, nanoszony starym ławkowcem nie powinien tworzyć warstwy grubszej niż 2 mm. Do utwardzenia i wyschnięcia potrzebuje on w zależności od temperatury pomieszczenia 5-10 godzin.

Wpierw należy ustawić pasy brzegowe z twardej pianki wokół ścian. Następnie proszek zawierający cement oraz ulepszony tworzywami sztucznymi zarobić wodą do konsystencji umożliwiającej wylewanie. Aby uzyskać prawidłowy stosunek mieszaniny należy stosować się bezwzględnie do instrukcji producenta. Do zamieszania potrzebna jest tzw. mieszarka koszowa, wzgl. łopatkowa, która może być po prostu zamocowana w wiertarce.

Po 5 minutowym dojrzewaniu jastrych jeszcze raz silnie się przemiesza. Konsystencja zarobionej mieszaniny jest prawidłowa wtedy, gdy po wylaniu na podłogę lekko się rozpływa. Gdy dodaje się wody lub proszku całość musi być ponownie starannie i mocno wymieszana.

Mieszaninę wylewa się pasami na powierzchni podłogi. Należy rozpoczynać od strony pomieszczenia, najdalej położonej od drzwi i posuwać się stopniowo do drzwi.

Rozdzielanie płynnego jastrychu trzeba lekko wspomagać kielnią gładzącą. Czas przerobu płynnego jastrychu wynosi mniej niż pół godziny. Do płaskiego rozlania się ważne jest, aby był on nanoszony i rozdzielany mokry na mokry. Po rozdzieleniu jastrych rozpływa się samodzielnie “do poziomu”. Do pełnego utwardzenia nie należy po nim chodzić.