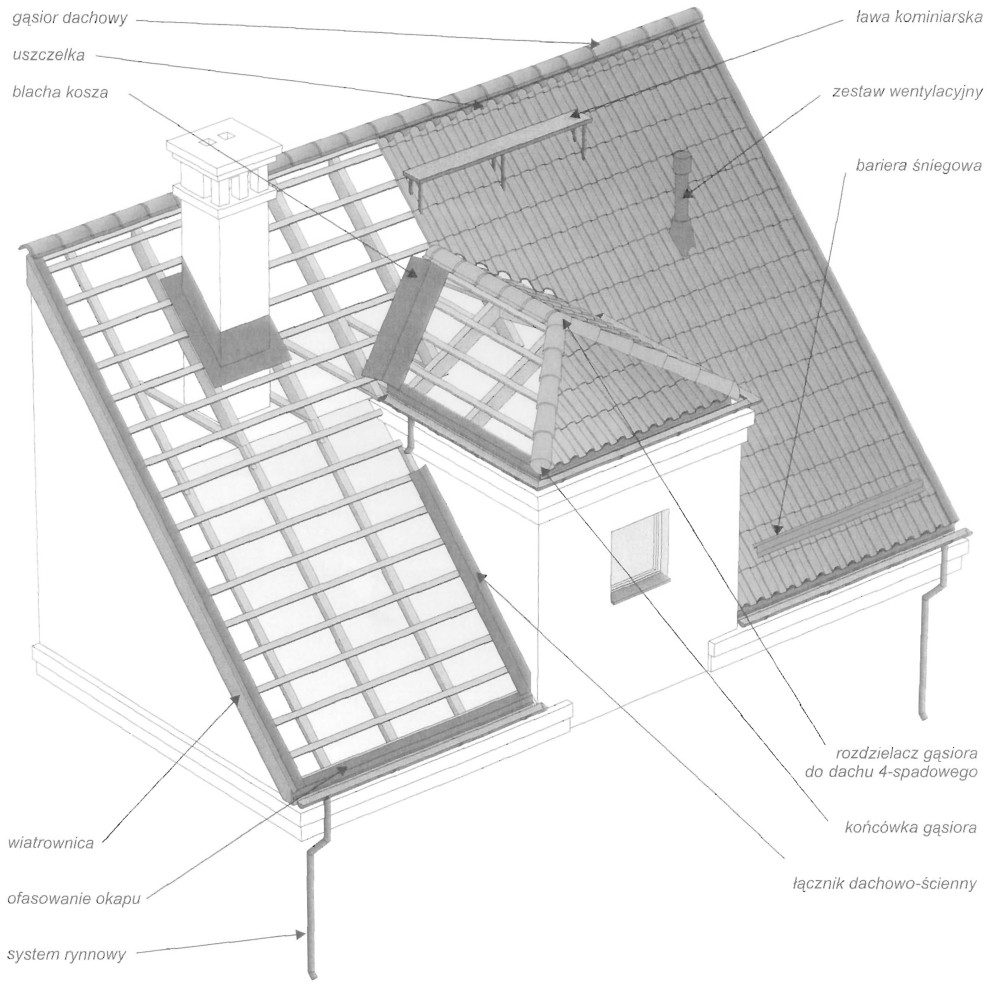

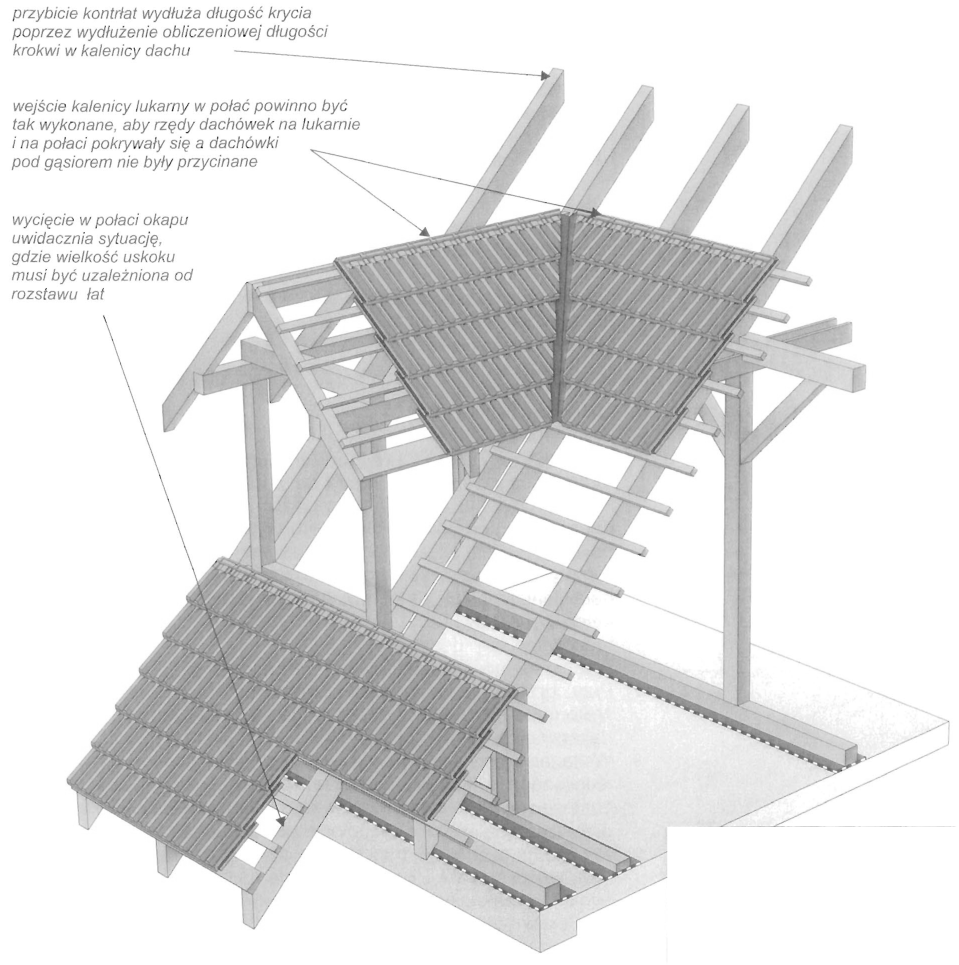

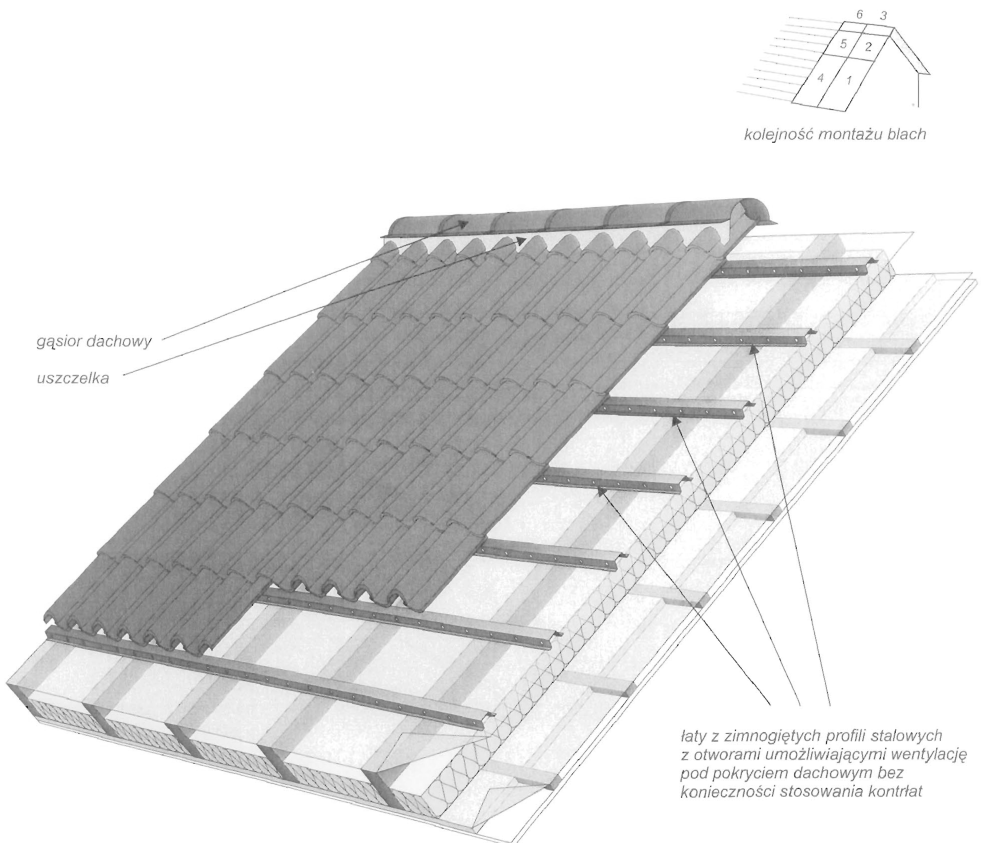

Pokrycie połaci dachowej wykonane z blach powlekanych profilowanych w kształcie dachówki, mocowanych na łatach z zimnogiętych profili stalowych.

Pokrycie połaci dachowej wykonane z blach powlekanych profilowanych w kształcie dachówki, mocowanych na łatach z zimnogiętych profili stalowych.

Do krycia dachów najczęściej stosowane są blachy powlekane, produkowane z wysokiej jakości stali pokrytej obustronnie powłokami cynkowymi o grubości około 275 g/m². Dzięki ocynkowaniu na powierzchni blachy następuje proces samogalwanizacji, czyli samoistnego pokrywania się cynkiem zarysowań i krawędzi cięć. Kolejne warstwy stanowią powłoki antykorozyjne – pasywacyjna i gruntująca. Od spodu układ powłok wykończony jest ochronną warstwą epoksydową. Od strony zewnętrznej wykończenie stanowić może poliester, poliester matowy, PVDF lub PURAL. Taki układ warstw zapewnia długoletnią odporność na korozję, trwałość blachy i stabilność koloru.

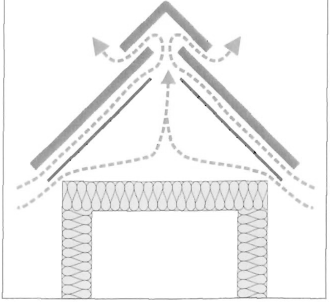

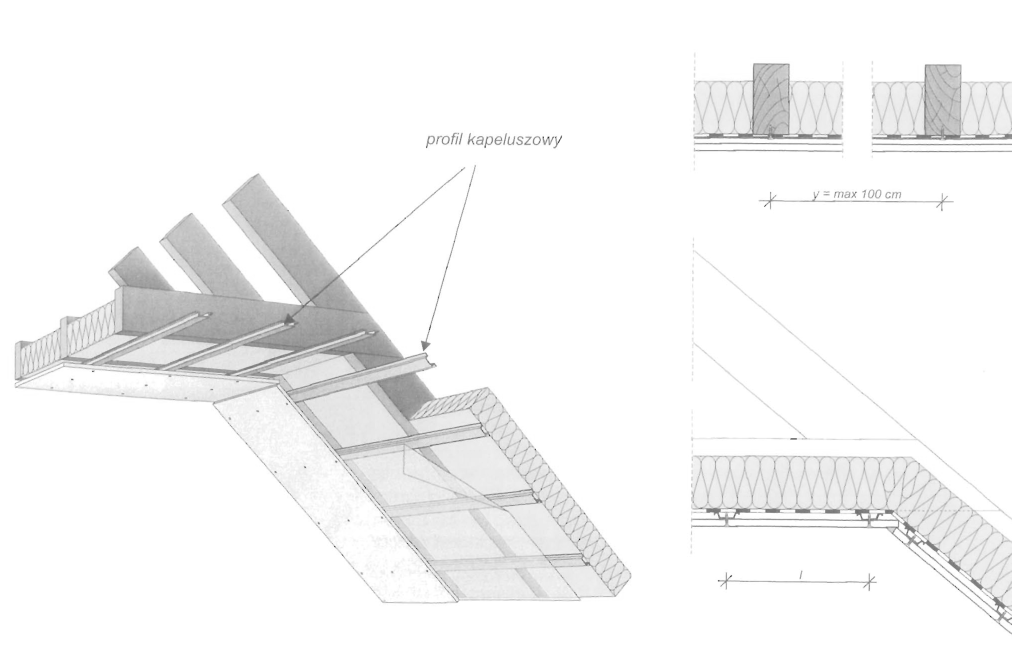

Do mocowania pokrycia z blachodachówki zalecane są łaty z zimnogiętych profili stalowych z otworami umożliwiającymi wentylację pod pokryciem dachowym, bez konieczności stosowania kontrłat.

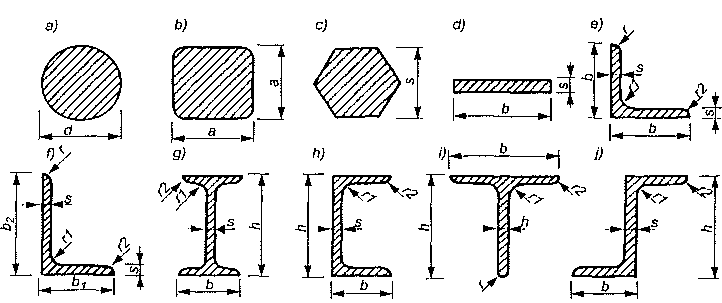

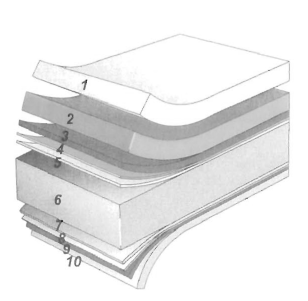

Blacha powlekana:

Blacha powlekana:

1,2)powłoka zewnętrzna – rodzaje powłok: poliester (lakier zewnętrzny z połyskiem), plastisol (gruba . elastyczna i odporna na uszkodzenia mechaniczne powłoka), PVF (pigment dający wysoki połysk, zapewniający twardość powłoki i trwałość koloru), PVF z lakierem bezbarwnym lub z powłoką metaliczną

3) podkład

4) warstwa pasywująca

5) cynk, min. 275 g/m²

6) blacha stalowa

7) cynk, min. 275 g/m²

8) warstwa pasywująca

9) podkład

10) epoks. lakier ochronny wewnętrzny