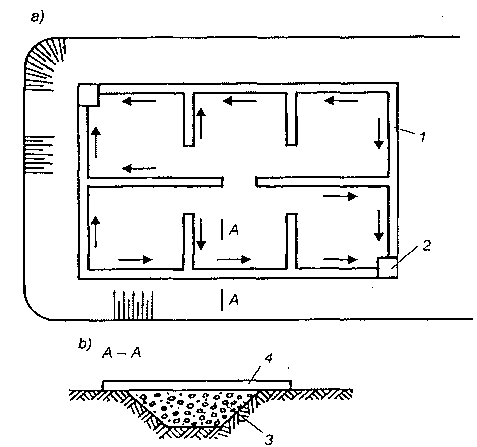

Pale wbijane, wpłukiwane i wwibrowane

W praktyce znalazły szerokie zastosowanie pale wbijane, które wykonuje się z drewna, stali i betonu (żelbetowe, sprężone).

Pale drewniane. Zasadniczym warunkiem stosowania pali drewnianych jest ich stałe zagłębienie poniżej poziomu wody gruntowej. Przy zmieniającym się poziomie wody gruntowej pale te ulegają szybkiemu zniszczeniu.

Najlepsze pale są z drewna sosnowego. Dąb jest dobry, ponieważ staje się bardzo twardy pod wodą, lecz jest drogi. Wykonywane są również pale ze świerku, jodły i innych drzew.

Pale wykonuje się z okorowanych okrąglaków prostowłóknistych, równych lub wyrównanych, bez sęków i większych pęknięć.

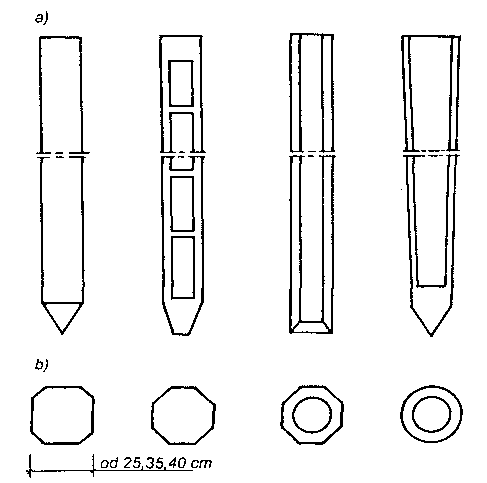

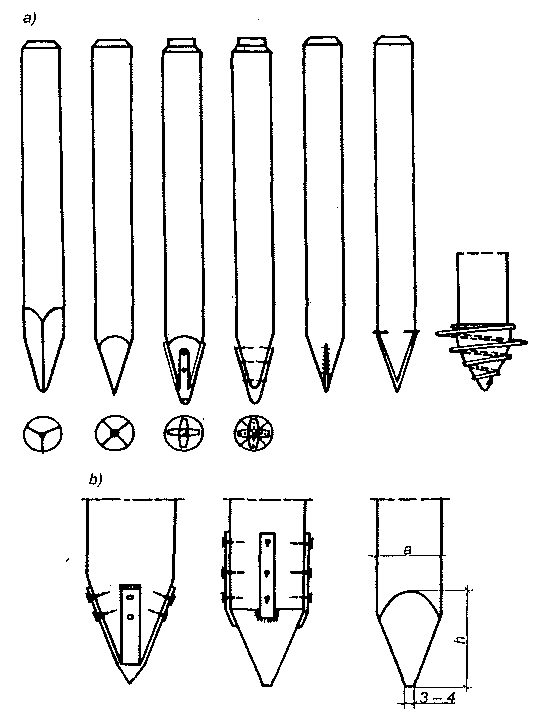

Pale drewniane z ostrzami i okuciami: a) widok, b) ostrza i okucia.

Pale drewniane z ostrzami i okuciami: a) widok, b) ostrza i okucia.

Wymiary pali: długość 4,0—10,0 m (najwięcej 12,0 m), średnica 20-25 cm dla pali o długości 4,0 m, 30-35 cm dla większych długości.

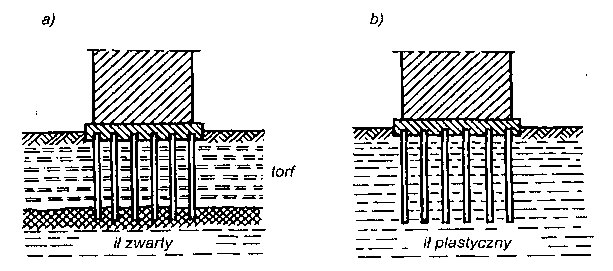

Pale stalowe. Pale stalowe są stosowane wtedy, gdy zachodzi potrzeba przebicia się do skały na dużą głębokość. Pale te wykonywane są z rur stalowych zabetonowanych. Rury stalowe o przekroju otwartym u dołu lub dwuteowym wbijane są w grunt. Po dojściu pala rurowego do skały lub wykazaniu przy wbijaniu większego oporu, oczyszcza się je z gruntu, który dostał się do wnętrza rury i zabetonowuje. Oczyszczania wewnątrz rury dokonuje się zwykle przez przedmuchiwanie sprężonym powietrzem lub przez użycie wody pod ciśnieniem.

Pale betonowe i żelbetowe. Pale betonowe i żelbetowe można podzielić na dwie zasadnicze grupy:

a) pale prefabrykowane,

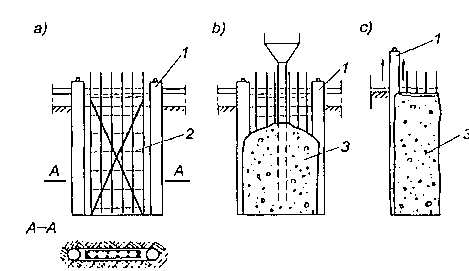

b) pale nabijane czyli wykonywane na miejscu w gruncie.

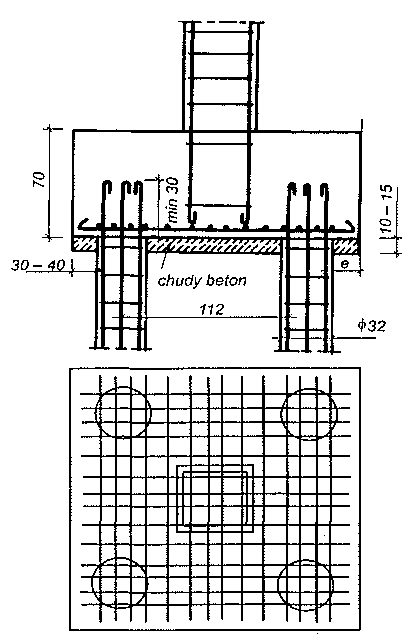

Pale prefabrykowane wykonywane są z żelbetu lub betonu sprężonego na poligonie lub w zakładzie prefabrykacji i zagłębiane są w grunt różnymi sposobami, najczęściej przez wbijanie.

Pale nabijane wykonywane są jako betonowe lub żelbetowe. Beton układany jest od razu w miejscu przeznaczenia w gruncie, w otworze wykonanym przy użyciu rury obsadowej (okładzinowej), a niekiedy i bez niej. Pale te są prostsze w wykonaniu od pali prefabrykowanych. Produkcja pali nabijanych odbywa się równocześnie z ich zagłębieniem w grunt na miejscu przeznaczenia, natomiast pale prefabrykowane wykonywane są w dwóch etapach, w zakładzie prefabrykacji i na miejscu przeznaczenia.