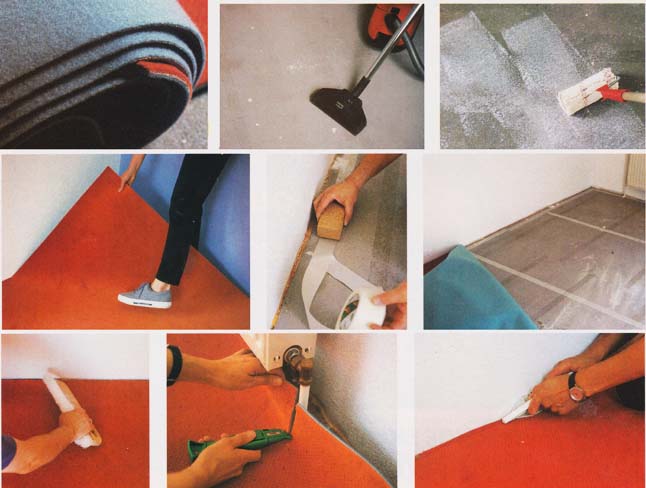

Jeżeli w rachubę nie wchodzi cało powierzchniowe klejenie wykładziny dywanowej lub ustalanie klejami umożliwiającymi ponowne zdjęcie wykładziny, wówczas istnieje możliwość mocowania dwustronna taśmą klejącą. Ten sposób układania może być rozważany tylko w wypadku jednoznacznie nadających się do tego wykładzin podłogowych. Przy większych powierzchniach układania ma tę wadę, że wykładzina przy silnym obciążeniu, po zamoknięciu, podczas gruntownego czyszczenia i przy obciążeniu kółkami foteli łatwo się “rozwałkowuje” i staje się nieładna.

Na bardzo porowatych podłożach (jastrychy cementowe, płyty gipsowo-włókniste lub płyty wiórowe) klej przywiera gorzej, niż na podłożach gładkich. Tutaj powinien być pokryty klejem pas brzegowy powierzchni układania o szerokości ca 10 cm.

Przed przyklejeniem układa się wykładzinę dywanową w jej przewidziane położenie, ustala ustawienie ciężkiego przedmiotu i dokładnie przycina na krawędziach. Używa się do tego ostrza hakowego. Podczas cięcia wykładzina musi być dobrze przytrzymywana.

Następnie odkłada się wykładzinę na brzegach i nakleja na podłogę dwustronną taśmę klejącą jej otwartą stroną w obszarze krawędzi. Taśmę klejącą trzeba bardzo starannie przetrzeć mocnym kawałkiem wykładziny dywanowej.

Obecnie ściąga się papierowy pas ochronny możliwie płasko nad podłogą, aby taśma klejąca się nie zluzowała. Wreszcie odkłada się ponownie wykładzinę dywanową i dobrze przyciska do taśmy klejącej kawałkiem drewna (kawałkiem deski z zaokrąglonymi krawędziami). Krawędzie do sąsiadujących pomieszczeń pokrywa się zamykającym profilem mosiężnym.

Wskutek wahań temperatury i wilgotności wielkość wykładziny nieznacznie się zmienia. Aby wykładzina dywanowa mogła się dostosować do klimatu pomieszczenia powinna ona być wyjęta z opakowania dwa dni przed układaniem i rozwinięta na podłodze.