Jeżeli przy wykańczaniu wnętrz nowych budynków, przy odnawianiu starych budynków lub przy przebudowie konieczne jest stworzenie podłoży pod wykładziny podłogowe, nadarza się tu okazja do równoczesnego wykonania warstw izolujących cieplnie i przeciwdzwiękowo. Jeżeli nie stosuje się przy tym elementów suchego jastrychu, które są już wyposażone w podkładki z twardej pianki (tzw. elementy zespolone), to podłoże izoluje się płytami z materiałów izolacyjnych, na których układa się następnie elementy jastrychu.

Jeżeli przy wykańczaniu wnętrz nowych budynków, przy odnawianiu starych budynków lub przy przebudowie konieczne jest stworzenie podłoży pod wykładziny podłogowe, nadarza się tu okazja do równoczesnego wykonania warstw izolujących cieplnie i przeciwdzwiękowo. Jeżeli nie stosuje się przy tym elementów suchego jastrychu, które są już wyposażone w podkładki z twardej pianki (tzw. elementy zespolone), to podłoże izoluje się płytami z materiałów izolacyjnych, na których układa się następnie elementy jastrychu.

W handlu materiałów izolacyjnych i na targach budowlanych można znaleźć najróżniejsze płyty izolacyjne, które można zastosować przy budowie podłoży. Najczęściej stosuje się płyty izolacyjne z włókien mineralnych lub twardej pianki. Niektóre targi j budowlane oferują płyty izolacyjne z miękkich włókien : spilśnionych lub z korka, które z ekologicznego punktu widzenia nie budzą zastrzeżeń. Następujące wstępne rozważania przed budową podłogi z płytami izolacyjnymi powinny pomóc, aby przy zamawianiu i zakupie uniknąć błędów i rozwiązań niepotrzebnych.

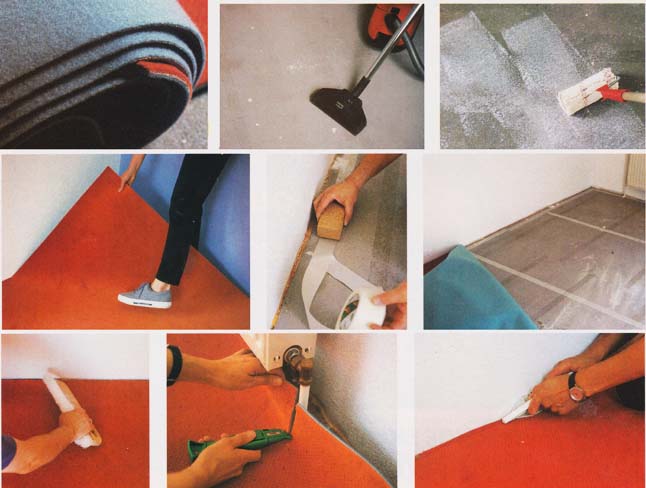

1. Nad masywnymi stropami konieczne jest ułożenie izolacji przeciwwilgotnościowej. Potrzebna jest do tego folia polietylenowa o grubości co najmniej 0,2 mm. Folie powinny być rozłożone na płaskim, czystym i szczelnym stropie w ten sposób, by sąsiadujące ze sobą pasy nakładały się na siebie na co najmniej 30 cm. Pasy folii mogą być również ze sobą sklejane. Poza tym folia powinna wychodzić na ok. 10 cm na otaczające ściany. Aby zapewnić rzeczywiście pływające ułożenie płyt suchego jastrychu, tzn. ułożenie nie dotykającego ścian, stawia się wokół, przy ścianach krańcowe pasy materiałów izolacyjnych o grubości około 2 cm.

2 Płyty izolacyjne suchego jastrychu z włókien mineralnych można po prostu przecinać nożem. Układanie powinno się odbywać z przestawieniem szczelin, a nie na szczeliny krzyżowe, płyty izolacyjne muszą być ułożone ściśle do siebie.

Szczelina, powstająca wokół podczas układania elementów suchego jastrychu pozostaje przepuszczalna dla powietrza poprzez brzegowe pasy materiału izolacyjnego. Po ułożeniu suchego jastrychu obcina się nożem materiał izolacyjny i wystający ponad podłogą.

3 Dla izolacji cieplnej najniższego surowego stropu, albo najwyższego stropu między-piętrowego domu zaleca się wykonanie podłogi na legarach. Również tutaj strop betonowy musi być wpierw gruntownie oczyszczony z resztek zaprawy, zanim nie zostanie położona folia polietylenowa jako izolacja przeciwwilgotnościowa.

Odstęp legarów podłogowych zależy od przewidzianej grubości elementów suchego Jastrychu (np. płyt wiórowych), względnie – przy bezpośrednim układaniu elementów gotowego parkietu na legarach podłogowych -wg wytycznych układania producenta parkietu. Przy zakupie płyt izolacyjnych należy tak dobierać ich szerokość, aby mogły one być ściśle dopasowane pomiędzy legary podłogowe.

Legary podłogowe układa się luzem na pasach brzegowych materiału izolacyjnego o grub. 1-2 cm, gdyż przykręcenie ich do podłoża zniweczyłoby uzyskane polepszenie izolacji przed odgłosem kroków. Przy układaniu na legarach płyt wiórowych lub gipsowo-włóknistych przykręca się je budowlanymi wkrętami do legarów podłogowych.

4 Także do izolacji stropów z belek drewnianych można zastosować płyty izolacyjne z włókien mineralnych, twardej pianki, korka lub miękkich płyt pilśniowych. Powinny one być tak dobrane w swej szerokości, by mogły być ściśle dopasowane pomiędzy belkami.

Jeszcze lepsza izolację cieplną i przeciwdźwiękową uzyskuje się przez ułożenie płyt izolacyjnych w dwóch warstwach, o przestawionych szczelinach. Przy zakupie należy wówczas uwzględnić, aby grubość płyt odpowiadała mniej więcej połowie wysokości izolacji. W tym celu potrzebna jest podwójna ilość płyt izolacyjnych.

Fachowiec radzi

Dla uniknięcia przemakania i gnicia stropy drewniane nie mogą być w żadnym wypadku pokrywane foliami polietylenowymi.